dIXEL

Operating and Instructions Manual

1592006100

1592006100 XB570L GB r1.0 04.11.2004.doc

XB570L

1/6

XB570L

BLAST CHILLER - QUICK CHILL AND HOLD FUNCTION

Contents

General warning _______________________________________ 1

General Features ______________________________________ 1

Mounting & Installation __________________________________ 1

Electrical Connections __________________________________ 1

Connections __________________________________________ 1

Frontal panel _________________________________________ 1

Front Panel Commands _________________________________ 2

How To Select A Cycle. _________________________________ 2

How To Start The Selected Cycle. _________________________ 2

10. How to temporarily stop the running cycle. __________________ 2

11. How to definitively stop the cycle. _________________________ 2

12. How To Modify The Set Point Of The Hold Mode. _____________ 2

13. How to start a manual defrost. ____________________________ 2

14. How A Cycle Is Done. __________________________________ 2

15. Function And Parameter Programming Menu ________________ 3

16. Accessing “Pr2” and SECURITY CODE input ________________ 4

17. List of parameters______________________________________ 4

18. Printer management____________________________________ 5

19. IV configurable relay. ___________________________________ 5

20. Digital configurable input. ________________________________ 5

21. ALARM SIGNALS _____________________________________ 5

22. Technical data ________________________________________ 6

23. Standard Value of the cycles._____________________________ 6

24. Standard Values of the parameters.________________________ 6

1. General

warning

1.1

PLEASE READ BEFORE USING THIS MANUAL

•

This manual is part of the product and should be kept near the

instrument for easy and quick reference.

•

The instrument shall not be used for purposes different from those

described hereunder. It cannot be used as a safety device.

•

Check the application limits before proceeding.

1.2

SAFETY PRECAUTIONS

•

Check the supply voltage is correct before connecting the instrument.

•

Do not expose to water or moisture: use the controller only within the

operating limits avoiding sudden temperature changes with high

atmospheric humidity to prevent formation of condensation

•

Warning: disconnect all electrical connections before any kind of

maintenance.

•

The instrument must not be opened.

•

In case of failure or faulty operation send the instrument back to the

distributor or to “Dixell s.r.l.” (see address) with a detailed description of

the fault.

•

Consider the maximum current which can be applied to each relay (see

Technical Data).

Ensure that the wires for probes, loads and the power supply are separated

and far enough from each other, without crossing or intertwining.

•

Fit the probe where it is not accessible by the end user.

•

In case of applications in industrial environments, the use of mains filters

(our mod. FT1) in parallel with inductive loads could be useful.

2. General

Features

The series XB has been created for fast chilling or freezing goods according

to international food safety standards.

There are FOUR types of cycles:

•

The CYCLES: Cy1, Cy2, Cy3, Cy4 are pre-set according to the most

common cycles used in food - safety applications; the user can select

one of them according to his own requirements and modify it as he

wants.

•

Any cycle can be manually terminated before the normal.

•

Any cycle can use the third probe like an “insert probe”, it measures the

internal temperature of the product.

•

During the Cycle there are no defrosts and the fans are always on, a

defrost cycle can be done before any freezing cycle.

•

The cycle is divided up to 3 phases completely configurable by the user.

•

Each instrument is provided with an output for remote display XR REP,

which shows the temperature of cabinets or goods.

•

The XB570L controller is provided with internal real time clock and can

be connected to the XB05PR printer. This means that a report, which

includes all the main features of cycle, can be printed: start and end of

the cycle, length of the cycle, logging of the temperature of the cabinet

and goods.

3. Mounting & Installation

Model XB570L is a controller panel mounted, hole dims 150x31 mm, and

fixed with the screws. The ambient working temperature range should be

between 0÷60°C. Avoid locations subject to heavy vibration, corrosive gases

or excessive dirt. The same applies to the probes. Ensure ventilation around

the instrument.

4. Electrical

Connections

The instruments are provided with a screw terminal block to connect cables

with a cross section up to 2,5 mm

2

. Before connecting cables make sure the

power supply complies with the instrument’s requirements. Separate the

input connection cables from the power supply cables, from the outputs and

the power connections.

Do not exceed the maximum current allowed on

each relay

, in case of heavier loads use a suitable external relay.

4.1 PROBES

CONNECTION

The probes shall be mounted with the bulb upwards to prevent damages due

to casual liquid infiltration. It is recommended to place the thermostat probe

away from air streams to correctly measure the average room temperature.

Place the defrost termination probe among the evaporator fins in the coldest

place, where most ice is formed, far from heaters and from the warmest

place during defrost, to prevent premature defrost termination.

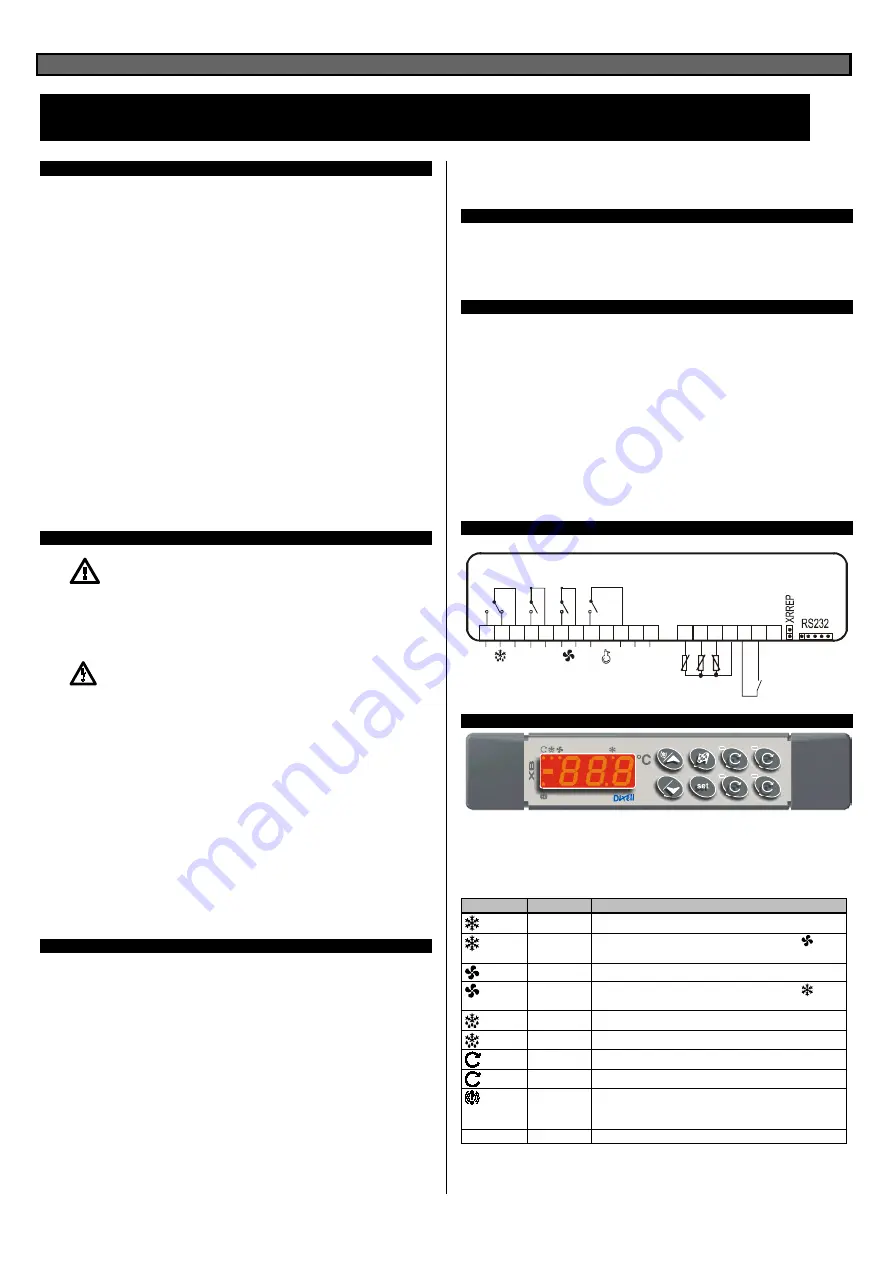

5. Connections

Di

gi

ta

l i

np.

Ev

ap.

Ins

er

t

Room

XB570L

Def.

Alarm/

AUX

Fan

12A

250Vac

MAX

20A

8A

250Vac

8A

250Vac

Supply

230Vac

Comp

8A

250Vac

19

13 14 15 16

12

5 6 7 8 9 10 11

1 2 3 4

17 18

6. Frontal

panel

Aux

1

2

3

4

6.1 MEANING OF THE LEDS’

A series of light points on the front panels is used to monitor the loads

controlled by the instrument. Each LED function is described in the following

table.

LED

MODE

ACTION

ON

- Compressor enabled

Flashing

- Programming Phase (flashing with LED

)

- Anti-short cycle delay enabled

ON

- Fans enabled

Flashing

- Programming Phase (flashing with LED

)

- Activation delay active

ON

- Defrost active

Flashing

- Drip time active

ON

- Freezing cycle or hold mode active

Flashing

- Instrument temporarily stop

ON

- Alarm signalling

- In “

Pr2

” indicates the parameter is also present

in “Pr1”

AUX

ON

- IV relay enabled