2

3

/

8

"

60 mm

a

b

c

d

200TS / 200TR DEADBOLT

Installation Instructions

MARK & DRILL HOLES

2

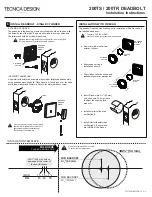

To adjust the backset hold the faceplate and :

a. Turn the latch to the RIGHT or clockwise

(CW) for a 2

3

/

4

" (70 mm) backset .

b. Turn the latch to the LEFT or counter-

clockwise (CCW) for a 2

3

/

8

" (60 mm) backset.

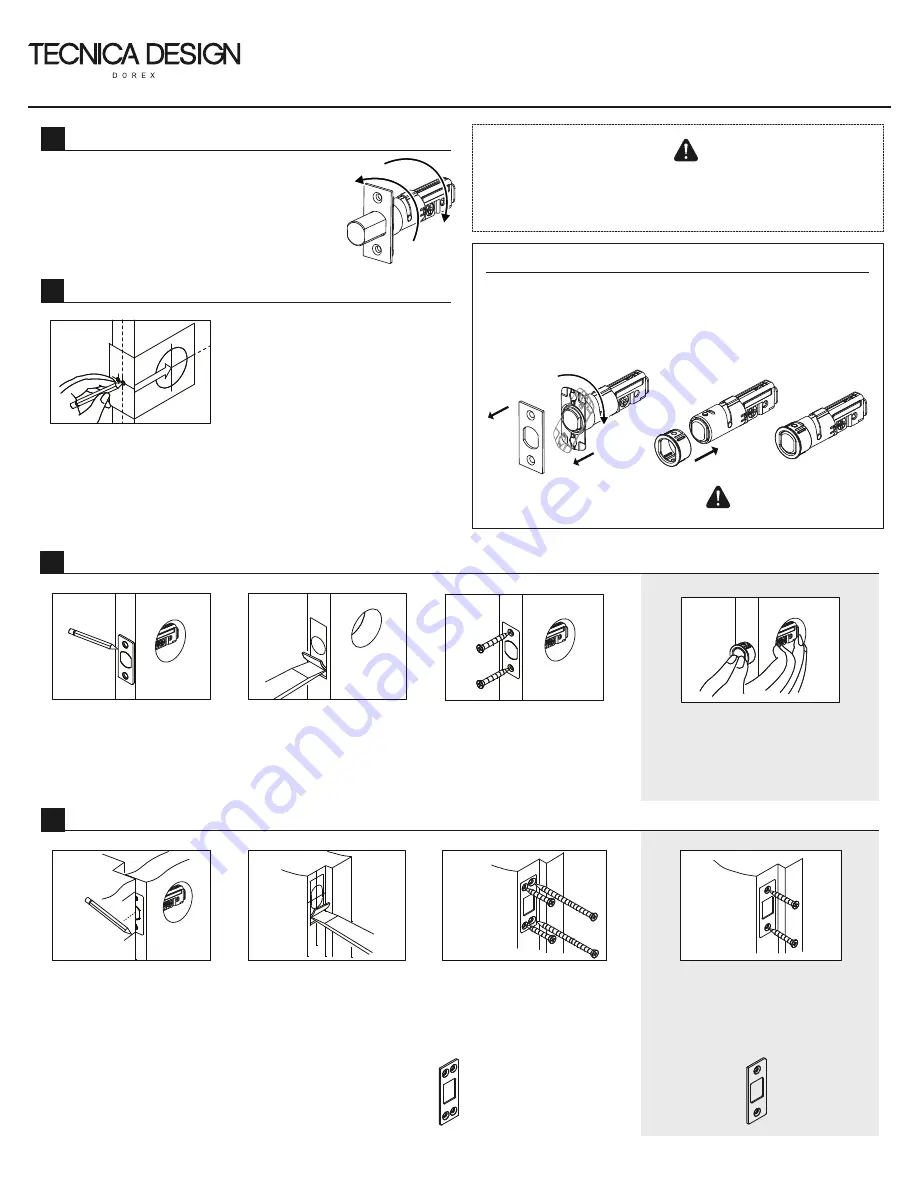

CONVERT MORTISE LATCH TO DRIVE-IN

a. Use flat-head screw driver to pry the faceplate off the backplate

b. Rotate or twist the backplate clockwise.

c. Remove backplate from the latch.

d. Insert drive-in ring as shown until ring snaps into position.

INSTALL DEADBOLT LATCH (WOOD DOOR)

3

Insert latch in edge hole and

orient it vertically as shown.

Trace the outline of the

faceplate and remove the

latch.

Chisel

5

/

32

" (4 mm) deep or

until the faceplate is flush with

the door edge.

FACEPLATE SIZE:

1 x 2

1

/

4

" (25.4 x 57 mm)

Insert latch and secure with

screws. To avoid wood

splitting, drill pilot holes for

the screws first.

a. Close the door as shown

to mark the centerline of

the strike.

b. Transfer horizontal

centerline mark to the

inside surface of the frame

and measure one half (½)

the door thickness from

the door stop to locate

the vertical centerline of

the strike.

c. Drill a 1" (25.4 mm) hole

1

1

/

4

" (32 mm) deep at the

intersection of the vertical

and horizontal centerlines.

d. Match strike screw holes

with vertical centerlines on

jamb and trace outline.

e. Chisel outline

1

/

16

" (1.5 mm)

deep. Strike should be

flush with jamb surface.

FOR DRIVE-IN

Insert latch in to the hole as shown

until flush with door edge. Use a

rubber mallet or wood block and

hammer if necessary.

INSTALL STRIKE (WOOD FRAME)

4

a, b

c, d, e

g

200TS-TR-INST 2018-03 1/2

REQUIRED TOOLS:

1. Phillips flat-head screwdriver

2. 1" (25.4 mm) chisel

3. 1" (25.4 mm) drill bit

4. 2

1

/

8

" (54 mm) hole saw

Do not use power tools when

installing door harware,

excessive screw or bolt

tightening may affect installation

or functioning of the hardware.

ADJUST TO REQUIRED BACKSET

ADJUST TO REQUIRED BACKSET

1

b

a

FACEPLATE

c

BACKPLATE

LATCH

DRIVE-IN

RING

d

a. Determine desired backset. Backset

on door should be the same as

backset of the deadbolt latch.

b. Determine the desired lock height

from the finished floor and mark the

lock's height centerline.

c. Fold template over door edge at

marked height and mark the center of

the 2

1

/

8

" (54 mm) hole on door surface

at required backset and drill.

d. Determine thickness of the door and

make center mark for 1" (25.4 mm) on

the door edge and drill. Drill

31

/

32

"

(25 mm) for drive-in installations.

NOTE:

Drill the 2

1

/

8

" (54 mm)

hole from BOTH SIDES of

the door to avoid splitting or

damaging the door surface.

f

FOR METAL FRAME

Prepare frame for 1

1

/

8

x 2

3

/

4

x

1

/

16

"

(29 x 70 x 1.6 mm) strike.

Insert strike and secure using

#8 x 1

1

/

8

" (32 mm) combo screws

as shown.

Insert strike and secure using 3"

(76 mm) long wood screws and

#8 x 1

1

/

8

" (32 mm) combo screws

as shown.

1

1

/

8

x 2

3

/

4

",

1

/

4

"

radius corners

29 x 70

mm

, 6

mm radius corners

1

1

/

8

x 2

3

/

4

"

29 x 70

mm

LATCH

FACEPLATE

2

3

/

4

"

70 mm

We recommend an

edge-bore of

31

/

32

" (25 mm)

diameter for a tighter fit.