OPERATOR MANUAL

IMPORTANT INFORMATION, KEEP FOR OPERATOR

Information contained in this document is known to be current and accurate at the time of printing/creation. Unified Brands recommends referencing our

product line websites, unifiedbrands.net, for the most updated product information and specifications. The company reserves the right of final interpretation

of the user manual. Information subject to change without notice. © 2021 Unified Brands. All Rights Reserved. Unified Brands is a wholly-owned subsidiary

of Dover Corporation.

2016 Gees Mill Road, Suite 200, Conyers, GA 30013

888-994-7636, fax 888-864-7636

unifiedbrands.net

PART NUMBER PP MNL1102, REV. C (04/21)

This manual provides information for:

ECOARCH ENERGY EFFICIENT

VENTILATION SYSTEMS

THIS MANUAL MUST BE RETAINED FOR FUTURE REFERENCE. READ,

UNDERSTAND AND FOLLOW THE INSTRUCTIONS AND WARNINGS

CONTAINED IN THIS MANUAL.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance.

NOTIFY CARRIER OF DAMAGE AT ONCE

It is the responsibility of the

consignee to inspect the container upon receipt of same and to determine

the possibility of any damage, including concealed damage. Unified

Brands suggests that if you are suspicious of damage to make a notation

on the delivery receipt. It will be the responsibility of the consignee to file

a claim with the carrier. We recommend that you do so at once.

Manufacture Service/Questions 888-994-7636.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

NOTICE: Due to a continuous program of product improvement, Unified Brands

reserves the right to make changes in design and specifications without prior notice.

NOTICE: Please read the entire manual carefully before installation. If certain

recommended procedures are not followed, warranty claims will be denied.

MODEL NUMBER _________________________

SERIAL NUMBER _________________________

INSTALLATION DATE ______________________

EQUIPMENT DESCRIPTION

This manual covers three of the basic types of systems offered by Avtec:

MODULAR GREASE EXTRACTORS SERIES

Extractor ventilators are listed by UL and are built in accordance of NFPA-96 for

use with UL listed extinguishing systems for duct hood protection. These models

utilize high velocity removable grease extractors. The canopy contains a hidden

grease trough and removable cup. Surface, plenum and duct collar extinguishing

systems may be factory supplied.

ULTRAVIOLET (UV) SERIES

The EcoArch Energy Efficient Ventilation

UVc is a door assembly integrally

installed in the exhaust plenum of an

EcoArch canopy, consisting of UVc

filtration system designed for use in

the ventilation control of commercial

cooking operations of listed hood

systems. A depiction of this unit is

indicated at left.

The UVc filtration system consists of a Heraus manufactured UVc and Ozone

producing lamp used to reduce exhaust odors and grease deposit emissions

before they enter the exhaust duct system. The UVc light waves and ozone

producing lamp breaks the grease particles into smaller molecules which allow

an Ozone reaction to occur chemically. Like combustion, high temperature

separates the O-atoms in atmospheric Oxygen which then bonds to the grease

molecule causing oxidation. Similarly, in UVc technology, the extra O-atom in the

Ozone splits from the ozone molecule and attaches itself to grease molecule

causing oxidation but without the high temperature, which results in the

reduction of duct cleaning, cleaning costs and risks of potential grease fires.

The EcoArch Energy Efficient Ventilation UVc is manufactured with Type 201

Stainless Steel; but, alternatively can be constructed using 200, 300 and 400

series stainless steel without adversely affecting the UVc filtration system

capabilities.

INSTALLATION INSTRUCTIONS

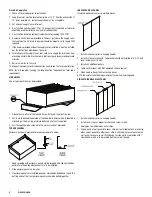

Avtec hoods are provided with adjustable hanging brackets designed to

receive 1/2” threaded rod with a 1/2” nut and washer. Supporting rods must

be connected to all factory supplied/installed brackets. Recommended hanging

height is 6’-6” above finished floor for canopies.

ALL AVTEC VENTILATION SYSTEMS MUST BE INSTALLED IN ACCORDANCE

WITH NFPA-96, REMOVAL OF SMOKE AND GREASE-LADEN VAPORS FROM

COMMERCIAL COOKING EQUIPMENT.

1. Check all local codes prior to installation. Special requirements may be

necessary depending upon building material construction.

2. Move crated hood to location of installation and very carefully uncrate hood.

3. Raise hood to proper hanging height.

4. Suspend hood from adequate roof supports using 1/2” threaded rods with

nuts and washers (See Fig. 1).

5. Level hood left to right and front to back.

6. Brackets are provided for hoods which are to be installed end to end or back

to back.

Bolt brackets together using 3/8” bolt through holes provided (See Fig. 2).

7. Install C channel where the ends of the hood meet and install T moldings on

front face of hoods where they join. High temperature silicone can be used

to install channel and T moldings (See Fig. 3).