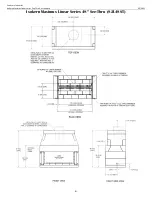

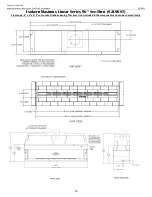

Isokern® MAXIMUS Linear Series

See-Thru Gas Fireplace and Chimney System

Installation, Operation, Maintenance and Owner’s Manual

Isokern Models: 82L48ST, 82L72ST, 82L96ST & 82L120ST

A PRODUCT OF EARTHCORE® INDUSTRIES, LLC

IMPORTANT

: This manual contains assembly rules, installation steps and guidelines, and use and maintenance instructions

for Isokern MAXIMUS Linear Series See-Thru gas appliances. This manual must become the property of and be reviewed by

all current and future users of this product. It is the responsibility of the distributor, general contractor, and the installer of

this product that the instructions in this manual are followed exactly and, further that the allowed gas log appliance used in

this product be installed in strict accordance with the gas log manufacturer’s listing and explicit installation and operation

instructions.

Be Sure to Read Entire Manual Before Beginning Construction.

Contents of this manual may change without prior notification.

PFS Report No. F19-161

USA: ANSI Z21.50 - 2019

Canadian: CSA 2.22- 2019

Issued: February 2021

Revision: 000

©2020 Earthcore Industries, LLC

THESE FIREPLACES ARE DESIGNED FOR USE WITH:

PROPANE (LP) OR NATURAL GAS (NG), ONLY

THIS MANUAL CAN ONLY BE REPRODUCED IN ITS ENTIRETY

INSTALLER: Leave this manual with the appliance

CONSUMER: Retain this manual for future reference

Do not install the Isokern MAXIMUS Linear Series

Gas Fireplace in a manufactured home or mobile

home or recreational vehicle.

—

This appliance complies with National Safety and

is tested and listed to ANSI/CSA Z21.50 – 2019 as

vented gas fireplaces.

—

Installation must conform to local codes. Check

local codes prior to installation. In the absence of

local codes, installation must conform with

current National Fuel Gas Code, ANSI Z223.1.