2

100P E

statE

B

roadcast

s

PrEadEr

ASSEMBLY and OPERATING INSTRUCTIONS

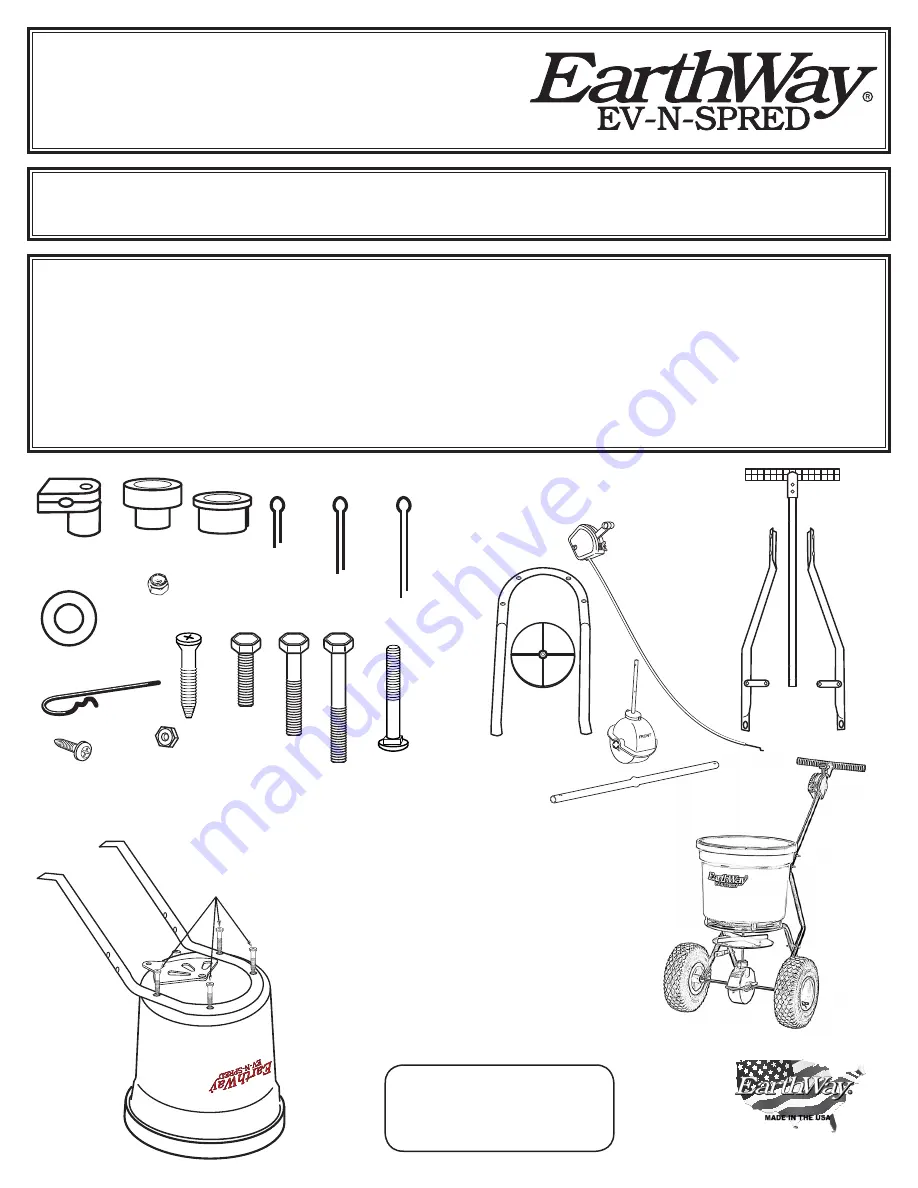

Lower

Housing Clip

Axle

Bushing

Axle

Bearing

⅛ x ¾”

Cotter Pin

⅛ x 1¾”

Cotter Pin

⅛ x 1¼”

Cotter Pin

#12 x 1¼”

Flat Head Screw

¼-20 x 1¾”

Carriage Bolt

¼-20

Lock Nut

Axle

Washer

Agitator

¼-20

Hex Nut

#10 x ⅝”

Screw

¼-20 x

1¼” Bolt

¼-20 x

1½” Bolt

¼-20 x

2” Bolt

FRAME

IMPELLER

CONTROL

ASSEMBLY

UPPER HANDLE

ASSEMBLY

DRAW BAR

&

BRACE ASSEMBLY

GEARBOX

AXLE

1.

Remove and identify all loose parts from carton

.

(Qty 4) #31105

#12 X 1¼”

Flat Head Screw

9-2014 Pt.# 52159

PAGE 1

2.

Position the Hopper on its top as shown

to the left. Install frame using (4) #12 x

1¼” Flat Head Phillips screws.

TIGHTEN

THESE NOW - use care to not over tighten

HELPFUL HINTS:

READ THE DIRECTIONS BEFORE ASSEMBLY

;

If your spreader does not spread evenly, be sure the FRONT on the gear box points to the front of the spreader. The

impeller must turn clockwise. Reversing the gearbox will cause the impeller to turn counter clockwise. Clean the impeller

plate after each use. Fertilizer stuck on the impeller blades will cause uneven spreading.

;

Your spreader is designed to be pushed at three miles per hour, which is a brisk walking speed. Slower or faster speeds

will change the spread patterns. Wet fertilizer will also change the spread pattern and flow rate. Clean and dry your

spreader thoroughly after each use. Coat all metal surfaces (inside & outside of chassis tubes) with light oil or silicon spray

to help prevent corrosion. Wash between the shut off plate and bottom of the hopper.

Do not use powdered materials.

;

Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

PLEASE CALL

IF YOU ARE MISSING ANY PARTS, HAVE ANY DIFFICULTY IN ASSEMBLY, OR HAVE ANY QUESTIONS

REGARDING THE SAFE OPERATION OF THIS SPREADER. THIS MODEL INCLUDES

LIFETIME TECHNICAL SUPPORT

SUPPORT HOT LINE: 574-848-7491 or 800-294-0671,

:

tEchsuPPort

@

Earthway

.

com

MADE IN THE USA

Warning

Remove agitator when

using Rock Salt to prevent

gearbox damage