44249

13

16

17

31

24

28

23

25

26

9

11

12

14

29

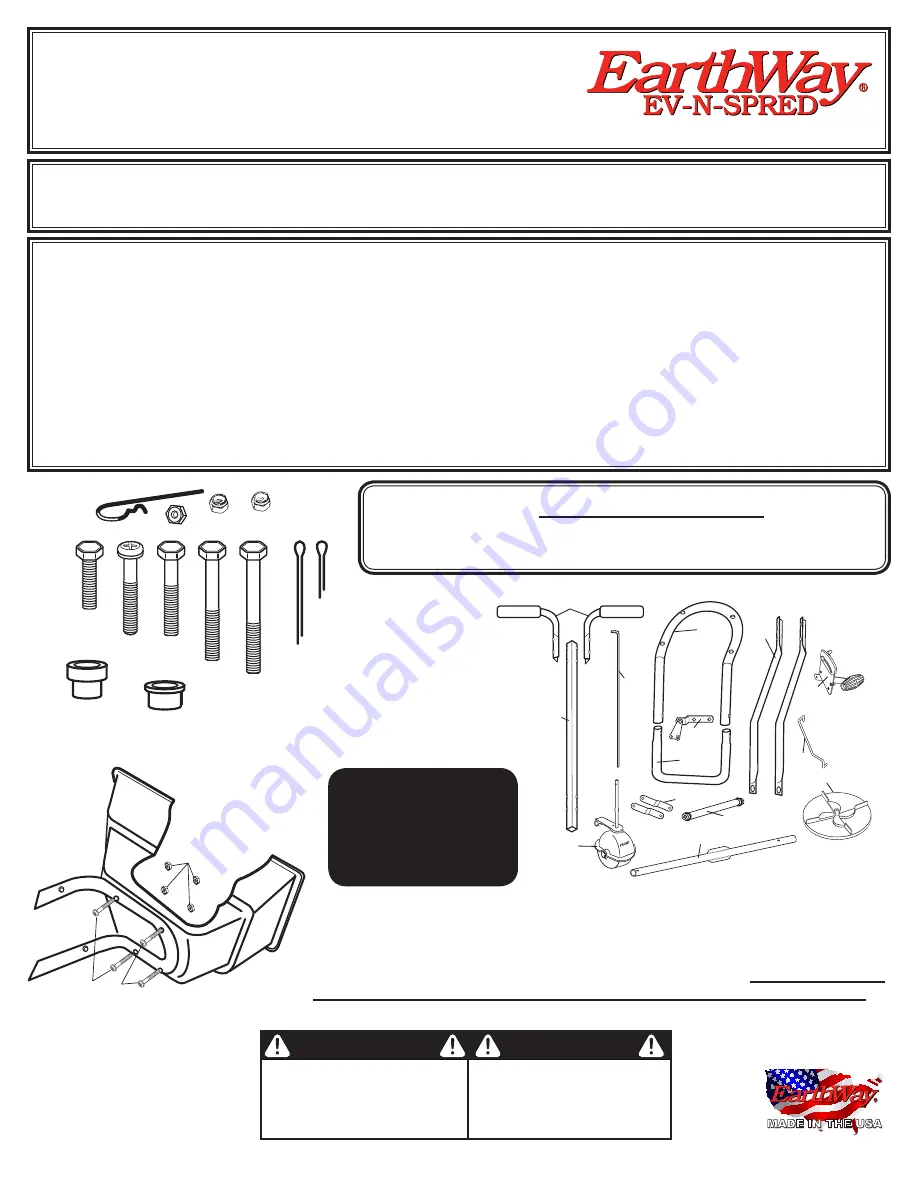

32103

Qty 8

32100

Qty 2

33117

Qty 1

36300

Qty 6

12152

Qty 2

12148

Qty 2

33109

Qty 1

36214

Qty 4

33108

Qty 1

36210

Qty 2

31100

Qty 4

31106

Qty 2

31120

Qty 4

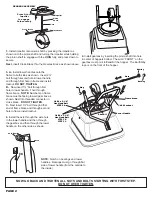

1.

Remove and identify all loose parts from carton

.

(Qty 4 #36214)

1/4-20 X 1½”

Phillips Panhead

(Qty 4 #36300)

1/4-20 SS Locknut

2.

Position hopper on side. Install frame using (4) 1/4-20 x 1-1/2” Pan Head Phillips

bolts and (4) 1/4-20 nylon insert locknuts. First put bolts through holes in frame

then through holes in bottom of hopper. Secure with locknuts.

TIGHTEN THESE

LOCKNUTS NOW - DO NOT TIGHTEN WITH POWER TOOLS. TIP: coat stainless

steel bolts with wax or grease before tightening to prevent them from seizing.

7-2018 Pt# 52164

PAGE 1

2170 Commercial

Broadcast Spreader

with SSC

ASSEMBLY and OPERATING INSTRUCTIONS

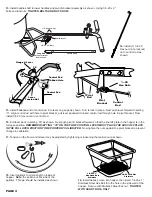

HELPFUL HINTS:

READ THE DIRECTIONS BEFORE ASSEMBLY

;

If your spreader does not spread evenly, be sure the FRONT on the gear box points to the front of the spreader.

The impeller must turn clockwise. Reversing the gearbox will cause the impeller to turn counter clockwise.

Clean the impeller plate after each use. Fertilizer stuck on the impeller blades will cause uneven spreading.

;

Your spreader is designed to be pushed at three miles per hour, which is a brisk walking speed. Slower or

faster speeds will change the spread patterns. Wet fertilizer will also change the spread pattern and flow rate.

Clean and dry your spreader thoroughly after each use. Coat all metal surfaces (

pay special attention to the

inside & outside of tubing - it’s easiest to do while assembling

) with light oil, Fluid Film

®

or silicon spray

to help prevent corrosion. Wash between the shut off plate and bottom of the hopper.

Do not use powdered

materials.

;

Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

PLEASE CONTACT US

IF YOU ARE MISSING ANY PARTS, HAVE ANY DIFFICULTY IN ASSEMBLY, OR HAVE ANY

QUESTIONS REGARDING THE SAFE OPERATION OF THIS SPREADER. THIS MODEL INCLUDES

LIFETIME

TECHNICAL SUPPORT

.

HOT LINE: 574-848-7491 OR 800-294-0671, EMAIL: TECHSUPPORT@EARTHWAY.COM

ROCK SALT and POWDERED MATERIALS should not

be used in this spreader as it will damage gearbox and

can void warranty. Use only granular materials.

WARNING

This product may contain a chemical known

to the State of California to cause Cancer, or

Birth Defects, or Other Reproductive Harm.

www.P65Warnings.ca.gov

ADVERTENCIA

Este producto puede contener un

componente químico conocida en el Estado

de California como causante de áncer,

defectos de nacimiento y otros daños al

sistema reproductor.

www.P65Warnings.ca.gov

Download the

NEW Rate Setting

App in the Apple

and Android App

Stores!