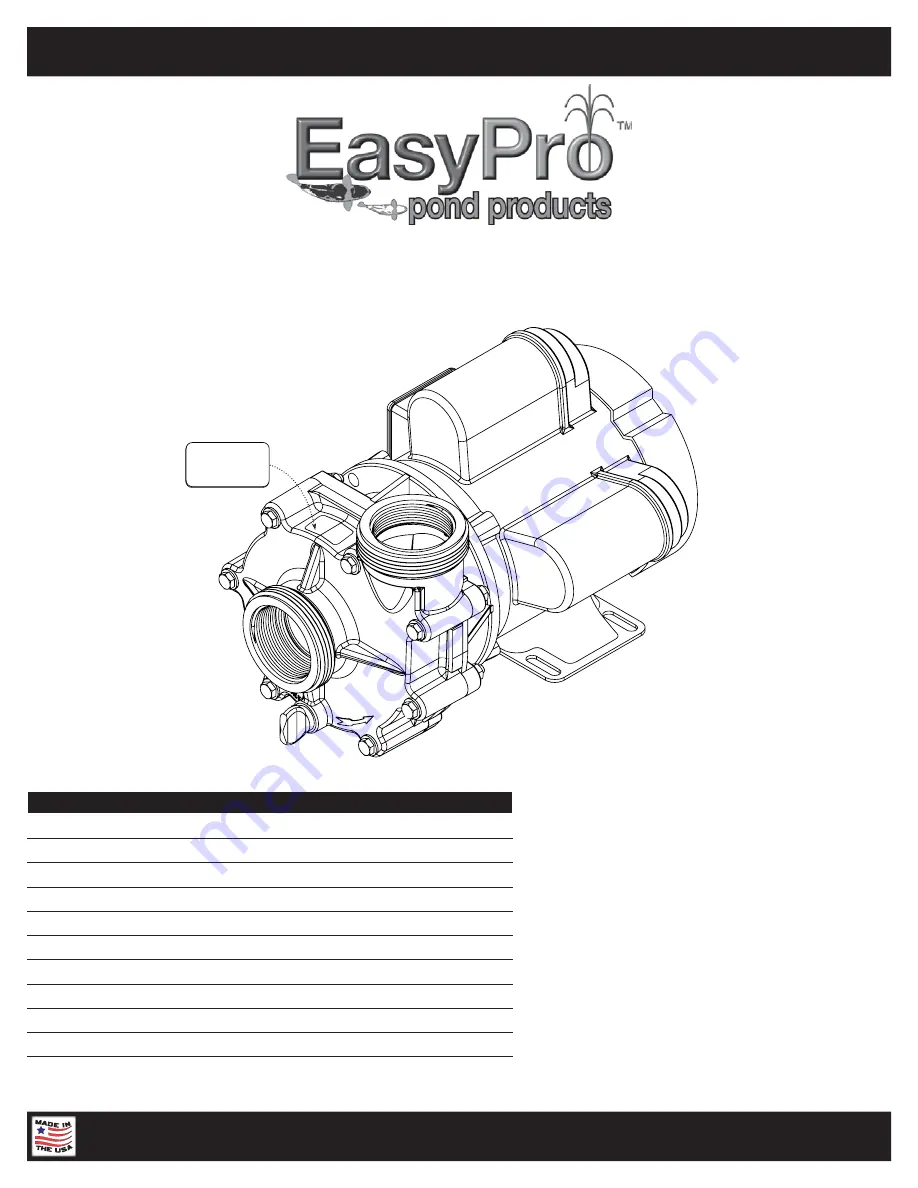

EX8800 • EX11200 • EX13200

Reliability You Can Count On!

© 2010 EasyPro, Inc

Pg. 1

TYPE:

STRAIGHT

CENTRIFUGAL

MOTOR: NEMA C FACE, 56J

HORSEPOWER: 1/2 (1750 RPM), 3 (3450 RPM)

INLET: 2" FNPT AND BUTTRESS THREAD PORTS

DISCHARGE: 2" FNPT AND BUTTRESS THREAD PORTS

MATERIAL: 40% GLASS-FILLED POLYPROPYLENE

HARDWARE:

STAINLESS

STEEL

OPTIONS:

SALTWATER

SERVICE

ACCESORIES: 90 CUBIC INCH STRAINER BASKETS (1.5" & 2")

SWING CHECK VALVES (1.5", 2", 3")

500 CUBIC INCH STRAINER BASKETS

(1.5", 2", 3")

WARNING: Please read completely before you install or operate your new pump! This is an external “out-of-pond” pump!

It is NOT submersible! Do NOT allow this pump to become submerged! Never run dry! Max. case pressure.- 65 PSI!

Please fi ll in for future reference:

MODEL: ________________________________________

SERIAL NUMBER: _______________________________

DATE PURCHASED: _____________________________

* Please fi ll out the warranty registration card in this manual

EasyPro

EX8800

S/N: XXXX-XXXXXX

Model

EX8800

EX11200 EX13200

Inlet

2"

2"

2"

Discharge

2"

2"

2"

Max Flow (gph)

8220

11160

13200

Max Head (feet)

22.3'

80.8'

81.7'

Max Power (watts)

450

2162

2595

Max Current (amps) 4.0 @ 115v 9.6@230v 11.5@230v

Volts

115/230

230

230

Motor HP

1/2

3

3

Motor Enclosure

TEFC

TEFC

TEFC

Impeller

8

6

7

Installation and Service Manual

Jolie

Products

Inc