Instructions for the Installation,

Operation and Maintenance

of W-SLC-7.2

Technical Data TD534-0501002U

Effective January 2013

1

1

1

1

1

2

3

3

3

3

3

4

5

7

7

7

8

8

8

8

8

8

9

9

9

Contents

Description

Page

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Order instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard conformance . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specification and technical data . . . . . . . . . . . . . . . . . . . . . .

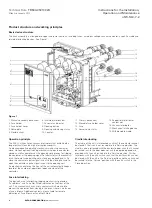

Product structure and working principles . . . . . . . . . . . . . . .

Main device structure . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse interlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cradle interlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

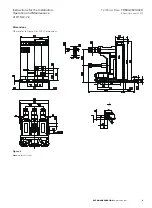

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

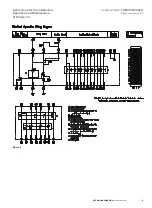

Schematic wiring diagram . . . . . . . . . . . . . . . . . . . . . . . .

Mounting, commissioning and operating . . . . . . . . . . . . . . .

Receiving, handling and storage . . . . . . . . . . . . . . . . . . . .

Commissioning and operating . . . . . . . . . . . . . . . . . . . . .

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection of vacuum interrupter . . . . . . . . . . . . . . . . . . .

Inspection of contact’s wear-out . . . . . . . . . . . . . . . . . . .

Inspection of mechanisms . . . . . . . . . . . . . . . . . . . . . . . .

Usage of fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement of fuses . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplied documents and accessories . . . . . . . . . . . . . . . . .

Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .