12/20/2017

EI505

INSTALLATION MANUAL, PLENUM

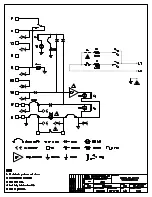

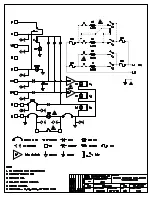

Size

C = Plenum

EM-DI ** *5 *

16W

x

16D

kW

Stages

10

=

9.6

kW

2

=

2

15

=

14.4

kW

3

=

3

20

=

19.2

kW

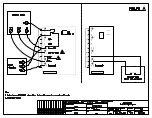

INTENDED USE – This product is approved and label certified for water source heat pumps or

air handlers at the blower discharge, upflow only.

Drawings:

EH503

ES501

XX017