Electrolux Dishwashing

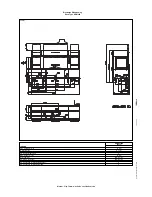

Rack Type WTM200

The Electrolux Dishwashing range is produced for customers with the highest conceivable demands for good

efficiency, economy and ergonomics for dishwashing operation. The product range comprises glasswashers,

undercounter dishwashers, hood type dishwashers, rack type dishwashers, flight type dishwashers and pot and

pan washers. The rack type dishwasher range is designed to be easily connected with the equipment included

in the Electrolux Handling System range, to create a functional and ergonomic dishwashing area. The rack type

dishwasher WTM200 has a capacity up to 200 racks per hour with 2 speeds (variable on-site). The range

consists of 6 electrically or steam heated models, available with or without Energy Saving Device (ESD).

534111

EASY TO INSTALL

•

Solid 3mm square stainless steel

sub-frame with bolt-together

construction that can be delivered

assembled or in modules to be

connected on site.

•

Stainless steel wash pumps ideal

for heavy duty usage installations.

•

Brass inlet valves as standard for

extra reliability at high incoming

water temperatures.

•

All rear positioned water tubes in

stainless steel.

•

Only one cable for electrical

connection.

•

Electrical and water connections

centralised in one area.

•

Service from the front and from

the side.

•

Pre-arrangements for automatic

detergent dispenser, energy

management device and HACCP

implementation (both basic as well

as integrated system).

FUNCTIONAL ZONES

•

Separate 45 litre pre-wash zone

first soil scrapping is performed.

Separate zone, at less than 35°C,

without chemicals for maximum

dirt removal and incorporates

automatic partial drain.

•

Power wash zone with 150 litre

wash tank with 2,2kW wash pump

supplying upper was arms, 1,1kW

wash pump supplying lower was

arms. Maximum water contact

wash arms for best possible

washing result.

•

Separate wash and rinse zones

so detergent does not mix with the

rinse aid and is always active.

•

Rinse area equipped with the

DUO-rinse system where the first

ramp is filled by the re-used final

rinse water, to eliminate any trace

of detergent, and the second ramp

is filled by hot fresh water to

guarantee sanitation of the items.

•

Atmospheric boiler combined

with the rinse booster pump for

perfect rinsing performances in

terms of sanitation, energy saving,

independence from the water

pressure on the network.

•

Incorporates non-return (air gap

class A) valve.