Summary of Contents for EHT6432

Page 1: ...AUS ERFAHRUNG GUT Gas hob EHT6432 user manual GB ...

Page 2: ...2 electrolux ...

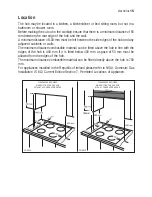

Page 22: ...22 electrolux Wiring diagram 1 TAPS IGNITOR SWITCHES 2 IGNITOR UNIT ...

Page 33: ...electrolux 33 ...

Page 34: ......

Page 35: ......