Summary of Contents for 6'3" WIDE THYME

Page 1: ......

Page 2: ......

Page 3: ......

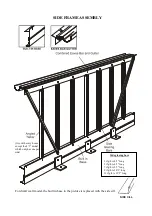

Page 11: ...REAR END ASSEMBLY dotted line indicates corner bracket base leg going into ground ...

Page 16: ...DOOR END ASSEMBLY ...

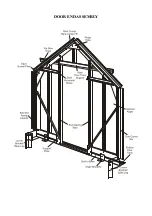

Page 19: ...DOOR FRAME ASSEMBLY ...

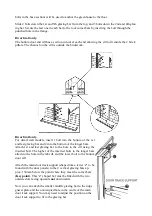

Page 21: ...ROOF VENT ...

Page 33: ...THYME 6 GLAZING PLAN BUILT IN BASE ONLY ...

Page 35: ...THYME 6 GLAZING PLAN DWARF WALL ONLY ...

Page 36: ...ELITE 1601 ...