M8 x 1.25

9 (80)

M10 x 1.25

17 (150)

M12 x 1.75

25 (222)

M16 x 1.50

55 (485)

M20 x 1.50

70 (620 )

KEYSTONE

PNEUMATIC ACTUATORS

FIGURE 738

Repair and maintenance instructions for F738 cylinders

DISSASSEMBLY INSTRUCTIONS

1. Remove the pneumatic cylinder from the valve.

2. Ensure the cylinder is in a clean

environment.

Actuator identification

3. Identify construction of cylinder model.

There are two types of Keystone pneumatic

cylinder:

a. Tie rod type - identifiable by external tie

rods.

b. Screwed end type - no external tie rods.

The enclosed seal kit has seals to suit both

types of cylinder. Discard unsuitable seals.

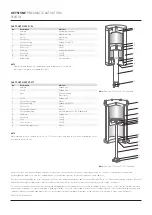

Double acting actuator

4. Dismantle the cylinder - if it is a tie rod style,

remove the tie rodnuts. If it is a screwed

style, unscrew the end covers.

SAFETY PRECAUTIONS

When an actuator is being installed or removed

from service, ensure all pneumatic and electrical

lines are isolated prior to commencing work.

NOTE

Use caution with spring return actuators as the

cylinder will return to its failed position when the air

supply is turned off or disconnected.

TORQUE TABLE

Tie rod thread

Torque Nm (lbs)

© 2017 Emerson. All Rights Reserved.

Emerson.com/FinalControl

VCIOM-02866-EN 17/11

NOTE

The piston and rod assembly do not normally require

dismantling. Check the condition of rod and barrel.

Replace if scored or damaged.

Spring return actuator

WARNING

Spring return cylinders contain potential energy

due to spring compression.

Emerson advises spring return cylinders are

returned to the factory for repair and maintenance.

Incorrect removal of head or end cap of spring

cylinder may result in injury or death.

NOTE

Remove all traces of solvents or detergents before

reassembly.

5. Select the appropriate seal kit for the

actuator model you have.

- Rod seal diameter varies for P3 cylinder

only (100 bore).

- Barrel o-rings are smaller section for

screwed end type pneumatic cylinder.

6. Lightly grease new seals with Castrol LMM

or equivalent.

7. Reassemble pneumatic cylinder in reverse

order of dismantling.

Take care not to damage threads, or to

pinch or damage seals.

8. For tie rod type pneumatic cylinder, fit tie

rod washers and nuts, then progressively

tighten the nuts on opposite sides.

Tighten to the required torque as per the

table below.

For screwed endcap style pneumatic

cylinder, ensure threads are thoroughly

cleaned with minimal lubrication. Use a pin

spanner to assist fitting the end caps to the

barrel and ensure the ports are aligned.

9. Refit pneumatic cylinder to valve and

reconnect air supply, avoiding ingress of any

contamination into ports.

10. Slowly stroke the actuator to ensure correct

alignment and operation.

NOTE

To minimize risk to personnel, Emerson recommend

the use of purpose built guards and shrouds.

Refer to the Emerson data sheet or consult factory

for details.