PT-32

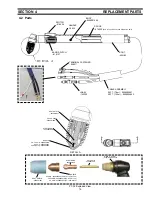

PLASMA ARC CUTTING TORCH

INSTRUCTION MANUAL

This manual provides installation and operation instructions for the following PT-32 torches:

P/N 0558001971- 25 ft (7.6 m), PT-32

P/N 0558001972 - 50 ft (15.2 m), PT-32

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe

practices for arc welding equipment, we urge you to read our booklet, "Precautions and Safe Practices for Arc Welding, Cutting,

and Gouging", Form 52-529. Do NOT permit untrained persons to install, operate, or maintain this equipment. Do NOT attempt

to install or operate this equipment until you have read and fully understand these instructions. If you do not fully understand

these instructions, contact your supplier for further information. Be sure to read the Safety Precautions before installing or

operating this equipment.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

F-15-440-B

January, 2002

Torches and torch body assemblies purchased individually are supplied without electrode, nozzle, heat shield and valve pin. Order

individual components shown on pages 9 or 15.