1

F-9040-P

May, 2009

INSTRUCTIONS for

F-9040-

P

I. DESCRIPTION

The C-60 and C-60-S Machine Cutting Torches are

for use with any of the commonly used fuel gases such

as acetylene, natural gas, propane and many of the

proprietary gases. A minimum of 10 psi fuel gas pres-

sure is required for proper operation.

The basic difference between the C-60 and C-60-S

torches is in their overall length. The C-60 torch is ap-

proximately 6 feet long, while the C-60-S is approxi-

mately 2 1/2 feet long. The 1700-ACA-2 Power Cut-

ting Attachment is only for use with the C-60 torch.

II. INSTALLATION AND CONNECTION

A. INSTALLATION

1. A filter designed to screen out dirt and scale should

be installed upstream of the cutting oxygen regu-

lator which supplies the C-60 Torch. Use of a filter

reduces the possibility of accidental hose burn-

outs.

The 1-in. NPT Pipeline Filter Assembly (P/N

2116734) is recommended if the cutting oxygen

supply regulator is an Oxweld R-52 feeding a single

cutting station. In the case of multiple torch instal-

lations supplied by a single oxygen regulator, such

as an Oxweld R-83, filter (P/N 2116735) is recom-

mended.

2. A 1-in. quick opening full flow shutoff valve should

be installed in the cutting oxygen hose line at least

6 feet ahead of the torch and convenient to the op-

erating position.

3. For control of the preheat gases, “C” size oxygen

and acetylene needle valves should be inserted in

the preheat oxygen and fuel gas hose lines at least

6 feet ahead of the torch.

Standard commercial valves can be used after they

are cleaned and lubricated, to oxygen standards,

as described in maintenance procedures.

4. If using the 1700-ACA-2 Power Cutting Attachment

(10Y95) on the C-60, the ACV-4 Powder Pinch

Valve (16X36) should be installed in the powder

hose line about 5 feet ahead of the torch and con-

venient to the operator.

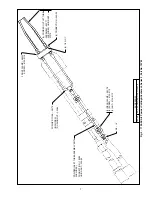

5. Connect the front clamp of powder cutting attach-

ment to front body of torch. Connect the two rear

clamps to the cutting-oxygen tube on the torch. (See

Fig. 2.)

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation and safe prac-

tices for oxy-fuel gas equipment, we urge you to read our booklet “Precautions and Safe Practices for Welding, Cutting and

Heating”, Form 2035. Do NOT permit untrained persons to install, operate, or maintain this equipment. Do NOT attempt to install

or operate this equipment until you have read and fully understand these instructions. If you do not fully understand these

instructions, contact your supplier for further information.

The cutting torches covered by these instructions are listed by third parties only when using parts manufactured

by ESAB Welding & Cutting Products, to the specifications on file with third party listed, and when they are used

in the gas service for which they are designed and listed. The use of other parts that cause damage or failure to the equipment will

void the manufacturer’s warranty.

C-60 and C-60-S

MACHINE CUTTING TORCHES and

1700-ACA-1

POWDER CUTTING ATTACHMENT

Be sure this information reaches the operator.

You can get extra copies through your supplier.