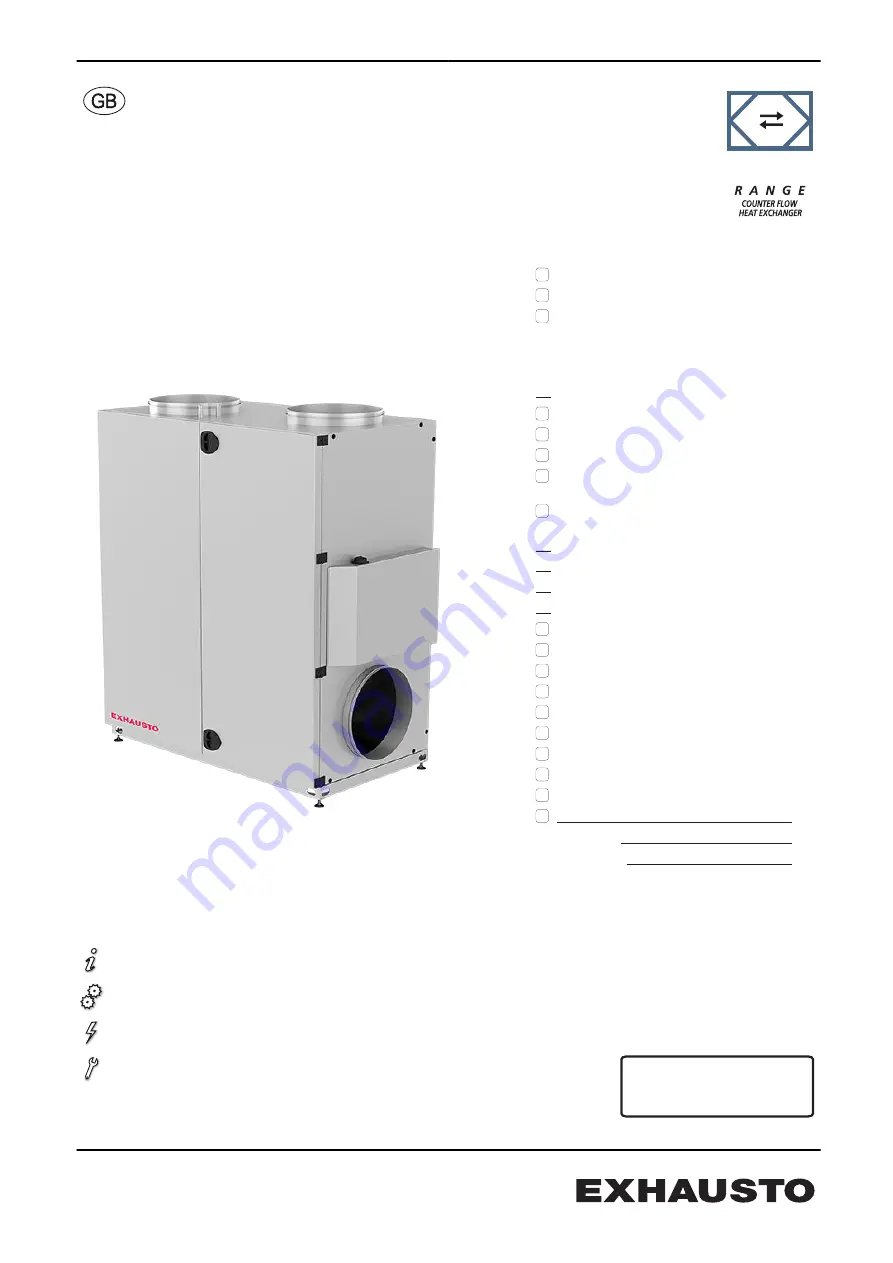

VEX160CF Vertical HCW

with EXact2 control

VEX100 CF

Product information........................................ Chapter 1 + 6

Mechanical assembly..................................... Chapter 2 + 3

Electrical installation.......................................Chapter 4

Maintenance...................................................Chapter 5

Unit supplied with (factory fitted):

The following accessories are supplied

separately:

VDI 6022

M5-compact filter, FP

F7-compact filter, FP

pieces, control panel, HMI

Motor valve, MVM ______K

vs

-value

Closing damper, LS500-24, (LSA exhaust)

Closing damper, LS500-24, (LSF outdoor)

Closing damper, LSR500-24, with

spring-return (LSAR exhaust)

Closing damper, LSR500-24, with

spring-return (LSFR outdoor)

pieces, Fire thermostat, BT40

pieces, Fire thermostat, BT50

pieces, Fire thermostat, BT70

pieces, Constant pressure control, MPT-DUCT

Motion sensor, MIO-PIR

Humidity sensor, MIO-RH

CO

2

-sensor, MIO-CO2-DUCT

CO

2

-sensor, MIO-CO2-ROOM

Temperature sensor, MIO-TS-DUCT

Temperature sensor, MIO-TS-ROOM

Control for external cooling unit, MXCU

Mounting base, MSV160V

TS-RPT-X

Prod.order no.:

Sales order no.:

Original instructions

3005706-2017-06-08

VEX160CF V_HCW

EXHAUSTO A/S

Odensevej 76

GB-5550 Langeskov

Tel. +45 65 66 12 34

Fax +45 65 66 11 10

exhausto@exhausto.dk

www.exhausto.dk

Summary of Contents for VEX100CF Series

Page 33: ...3005706 2017 06 08 33 36 ...

Page 34: ...3005706 2017 06 08 34 36 ...

Page 35: ...3005706 2017 06 08 35 36 ...

Page 36: ......