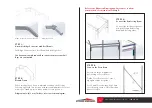

WHAT YOU’LL NEED

Drill / Impact Driver x2

Socket Set & Shifter

Ladder x2

Mallet

Forklift / Crane / Scissor Lift *

Tape Measure

Stringline

Level

Marking Pencil

Stanley Knife

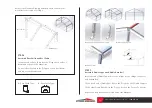

Warning read instructions carefully before use.

Recommended procedure to follow in this document.

For safety reasons it is recommended that at least four

persons set up any Crest Marquee.

Ensure area is free from any sharp objects & overhead objects.

www.extrememarquees.com.au 1300 850 832