FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

Tecnico\Prodotti\Manipolatore\Jp\Documenti\SM#Manuale JP_v102_ie.cdr - 11/01/07

FABER-COM srl - Via Romana 36/1 - 42028 Poviglio (RE) - Italy Tel. +39-0522-960428 Fax. +39-0522-969644 - www.fabercom.it

COM

FABER -

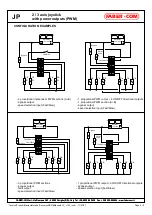

YA

YB

XA

XB

ZA

ZB

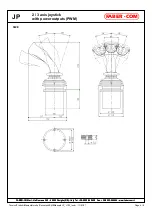

JP

Page 1 / 8

2 / 3 axis joystick

with power outputs (PWM)

Joystick

movements

third axis

THUMBWHEEL

(optional)

two principal axis

10Vdc ÷ 30Vdc

200 mA + output load (max 10A)

-20 ÷ 70 °C

from 100 to 2500 mA (with 10 mA resolution)

from 100 to 2500 mA (with 10 mA resolution)

50-60-70-85-100-125-150-200-250-300 Hz

2500 mA

3 PWM outputs at the same time

14 poles Molex minifit Jr. conn. with a 50 cm cable included

diameter 80 - width 90 mm

PRG2 serial keyboard

Power Supply Voltage

Current absorption

Working temperature range

PWM output minimum current

PWM output maximum current

Available

PWM frequency

ON/OFF output maximum current

Maximum number of manoeuvres

Connections

Under panel size

Programming Device

TECHNICAL SPECIFICATIONS

DESCRIPTION

JP is a 2 or 3 axis electronic joystick with power outputs, able to

directly control up to 6 proportional solenoid valves with PWM

outputs proportional to joystick movements.

Joystick movements are derived from the measurement of the

magnetic field produced by permanent ferromagnets; the

measurement is taken through redundant Hall effect probes. This

kind of probes are not subject to usury.

JP contains a microprocessor electronic card; this makes the

joystick very reliable and highly customizable.

Also the push button panel is customizable.

Main characteristics:

- you can control two or three proportional indipendent axis (4 or

6 PWM outputs) or just one proportional output (PWM) with 4 or

6 ON/OFF outputs

- optional "virtual cross" to forbid diagonal movements

- linear or parabolic output curve

- up to 3 speed set selectionable by two input

- straight BYPASS output, with delayed turn off

- FAULT output

- standard or capacitive dead man switch

- indipendent regulation (for each semiaxis) of

l

minimum current

l

maximum current

l

rise timeramp

l

fall timeramp

- PWM frequency adjustable from 50 to 300 Hz

- power supply voltage from 10Vdc to 30Vdc

- completely resinated electronic card

- third proportional axis THUMBWHEEL ready to mount

- provided with a 50 cm long unpluggable cable