T100699 Ref.1

E350/30

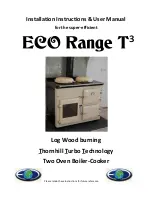

FOUR HOTPLATE RANGE

INSTALLATION and

SERVICING INSTRUCTIONS

IMPORTANT

The installer must ensure that the installation of the appliance is in conformity with these instructions and

National Regulations in force at the time of installation. Particular attention MUST be paid to -

BS7671 IEE Wiring Regulations

Electricity at Work Regulations

Health And Safety At Work Act

Fire Precautions Act

This appliance has been CE-marked on the basis of compliance with the Low Voltage and EMC Directives for

the voltages stated on the Data Plate

WARNING -THIS APPLIANCE MUST BE EARTHED

On completion of the installation these instructions should be left with the Engineer-in-Charge for reference

during servicing. Further to this, The Users Instructions should be handed over to the User, having had a

demonstration of the operation and cleaning of the appliance.

IT IS MOST IMPORTANT THAT THESE INSTRUCTIONS BE CONSULTED BEFORE INSTALLING AND

COMMISSIONING THIS APPLIANCE. FAILURE TO COMPLY WITH THE SPECIFIED PROCEDURES MAY

RESULT IN DAMAGE OR THE NEED FOR A SERVICE CALL.

PREVENTATIVE MAINTENANCE CONTRACT

In order to obtain maximum performance from this unit we would recommend that a maintenance contract be

arranged with AFE SERVICELINE. Visits may then be made at agreed intervals tocarry out adjustments and

repairs. A quotation will be given upon request to contact numbers below.

WEEE Directive Registration No. WEE/DC0059TT/PRO

At end of unit life, dispose of appliance and any replacement parts

in a safe manner, via a licenced waste handler.

Units are designed tobe dismantled easily and recycling of all

material is encouraged whenever practicable.

Falcon Foodservice Equipment

HEAD OFFICE AND WORKS

Wallace View, Hillfoots Road, Stirling. FK9 5PY. Scotland.

SERVICELINE CONTACT -

PHONE - 01438 363 000

FAX - 01438 369 900