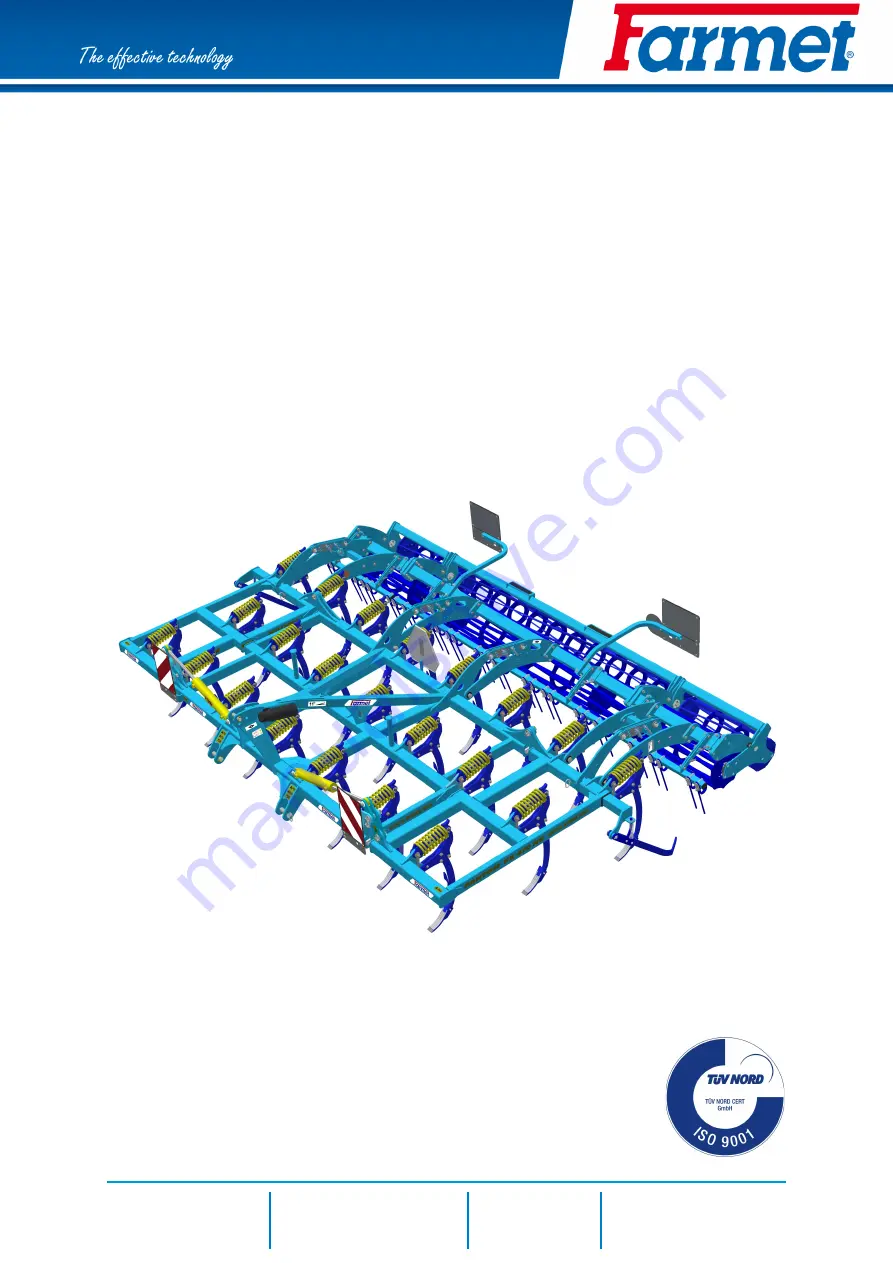

FANTOM

F

FX

X 4

47

70

0 N

NS

S

Edition:

3

Effective from:

1.1.2018

FARMET a.s.

Jiřinková 276

552 03 Česká Skalice, CZ

phone: +420 491 450 111

fax: +420 491 450 136

GSM: +420 774 715 738

IČ: 46504931

DIĆ: CZ46504931

www.farmet.cz

e-mail: farmet@farmet.cz

OPERATING MANUAL

F

FA

AN

NT

TO

OM

M

F

FX

X 4

47

70

0 N

NS

S

Summary of Contents for FANTOM FX 470 NS

Page 2: ...2 37 Prepared by Technical Department Farmet a s on 24 4 2019 changes reserved ...

Page 4: ...PREFACE 4 37 IMPORTANT READ CAREFULLY BEFORE USE KEEP FOR FUTURE REFERENCE ...

Page 6: ...PREFACE 6 37 ...

Page 14: ...WORK SAFETY LABELS Fig 1 Location of safety labels on the machine FANTOM FX 470 NS 14 37 ...