IMSS E3265

- 1 -

E3265

REV D 8/9/13

FEDERAL INDUSTRIES

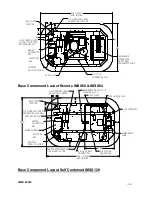

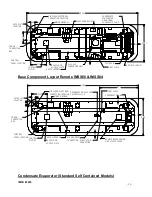

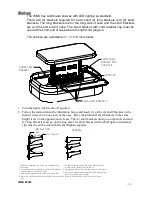

IMSS60, IMSS84 & IMSS120 MODELS

INSTALLATION & OPERATIONS MANUAL

KEEP THIS MANUAL FOR FUTURE REFERENCE

Engineering and technical data are subject to change without notice.

FEDERAL INDUSTRIES

P.O. Box 290

Belleville, WI 53508

Toll Free 1(800) 356-4206

WI Phone (608) 424-3331

Fax: (608) 424-3234