2561155A

REV. A 794

Printed in U.S.A.

INSTRUCTION SHEET

FOR

SIGNALMASTER™ MODELS SMC14 and SML4-30

SAFETY MESSAGE TO INSTALLERS AND USERS

People’s lives depend on your safe installation of our

products. It is important to read, understand and follow all

instructions shipped with the products. In addition, listed

below are some other important safety instructions and

precautions you should follow:

•

To properly install this light: you must have a

good understanding of automotive electrical

procedures and systems, along with proficiency

in the installation and use of safety warning

equipment.

•

When drilling into a vehicle structure, be sure

that both sides of the surface are clear of any-

thing that could be damaged.

•

In order for the light to function properly, a

good ground connection must be made. At a

minimum, it must be attached to a solid metal

body or chassis part that will provide an effec-

tive ground path as long as the light system is

to be used.

•

Locate light control so the VEHICLE and

CONTROL can be operated safely under all

driving conditions.

•

Do not attempt to activate or deactivate light

control while driving in a hazardous situation.

•

You should frequently inspect the light to en-

sure that it is operating properly and that it is

securely attached to the vehicle.

•

File these instructions in a safe place and refer

to them when maintaining and/or reinstalling

the product.

Failure to follow all safety precautions and instruc-

tions may result in property damage, serious injury, or

death to you or others.

I.

GENERAL.

The Federal SignalMaster™ Model SMC14 is an

economical, low profile, solid state, directional light control

that is designed to operate with two Federal Signal four-

lamp directional light assemblies (Model SML4-30). The

unit is reversed polarity protected to avoid damage if the

positive and negative power connections are connected

incorrectly.

This model provides three distinctive directional

signals: left arrow, right arrow, and center out. In addition,

an alternating flash pattern produces a warning signal for

use when a directional signal may not be appropriate.

When a directional signal is selected, the lamps are

individually illuminated in a sequential sweeping motion

until all eight lamps are illuminated.

II.

SPECIFICATIONS.

Input Voltage

11VDC to 16VDC.

Polarity

Negative ground only.

Operating Temperature

-30

°

C to +65

°

C.

Range

Standby Current

Zero amperes.

+BAT Fuse

25 amperes.

+IGN/BAT Fuse

1 ampere.

Output Drive

8, 27 watt lamps.

Capability (Total)

Flash Rate:

Directional

35 patterns/min.

Warn

60 patterns/min.

Dimensions:

Height

1-1/2"

Width

6-1/8"

Depth

5"

Shipping Weight

2.0 lbs

III. INSTALLATION.

WARNING

These lights are intended for

secondary

warn-

ing only. They are

not

intended for use as a

primary warning system.

A.

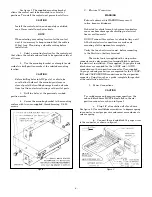

SignalMaster Light Assembly (Model SML4-30).

Install the light assembly as described in the

instructions packed with the mounting kit. Route the cable

near the eventual location of the control unit.

B.

Control Unit.

WARNING

When installing equipment inside air bag equipped

vehicles, the installer MUST ensure that the equip-

ment is installed ONLY in areas recommended by

the vehicle manufacturer.

Failure to observe this warning will reduce the

effectiveness of the air bag, damage the air bag, or

potentially damage or dislodge the equipment,

causing serious injury or death to you or others.