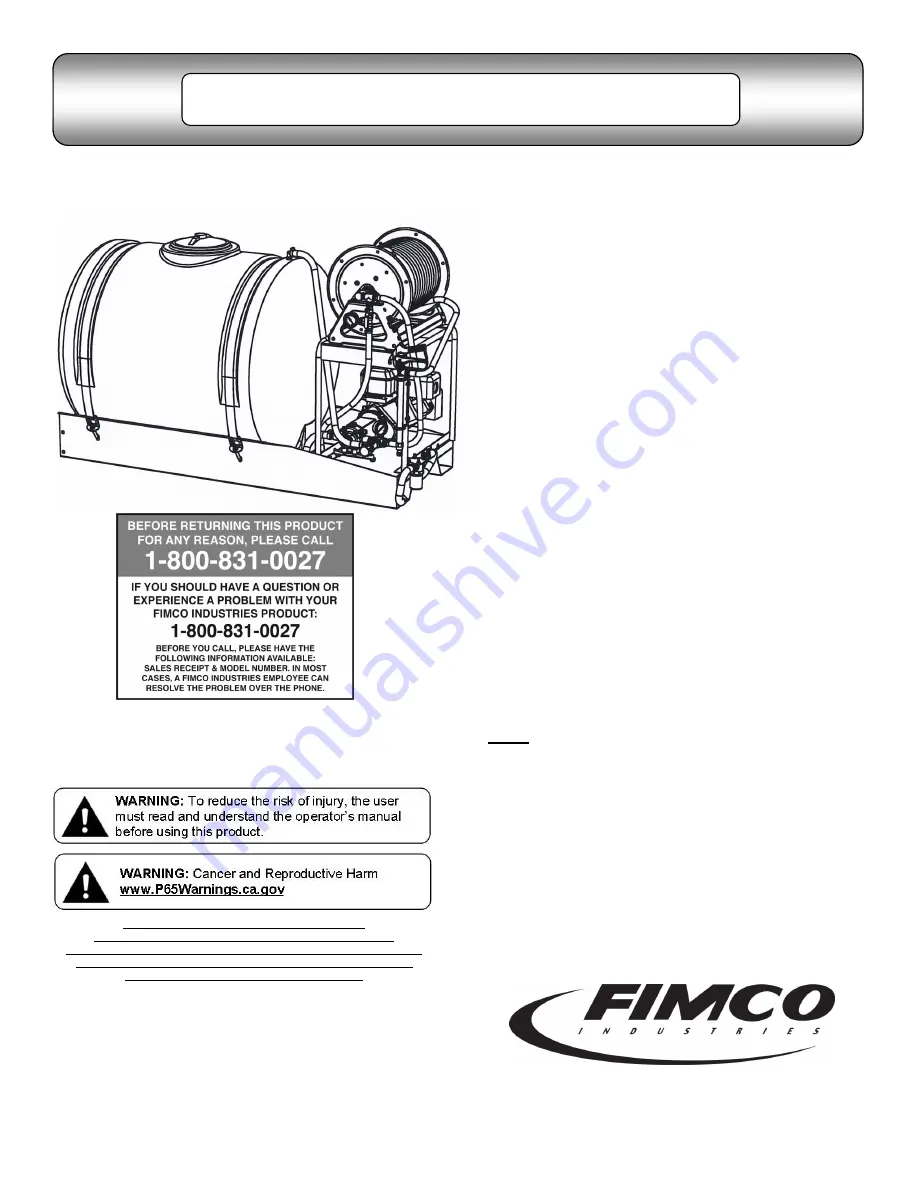

Page 1

General Information

Thank you for purchasing this product. The purpose of this

manual is to assist you in operating and maintaining your Skid

Sprayer.

www.fimcoindustries.com

1000 FIMCO Lane, P.O. Box 1700, North Sioux City, SD 57049

Toll Free Phone: 800-831-0027 : Toll Free Fax: 800-494-0440

[5004293

(12/18)]

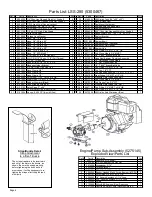

Model: LSS-280 (5300467)

(200 Gallon Lawn Service Skid Sprayer w/205cc B&S Engine)

Technical Specifications

200 Gallon Polyethylene Tank

205cc B&S Engine, 8.0 Gross Torque w/6:1 Gear

Reduction

8 Roller Pump - 10 GPM @ 250 PSI

Pressure Relief Valve

Handgun w/1/2” x 300’ of Hose

Delta Jet Agitation

Caution: When fully filled with water, this sprayer will

weigh approx. 2,065 lbs..

Consult the owner’s manual for your vehicle to verify

that you are within it’s load carrying capacity.

Retain a copy of your receipt for your unit,

as it will be required to validate any warranty service

Products are warranted against manufacturer or workmanship

defects for one year from date of purchase for home owner

usage and 90 days for commercial usage.

For technical assistance, visit our website @

www.fimcoindustries.com or call:

TOLL FREE @ 1-800-831-0027

Our Technical Support Representatives will be happy to help you.

To obtain prompt, efficient service, always remember to give the

following information…

Correct Part Description and/or part number

Model #/Serial # of your sprayer

Part descriptions and numbers can be obtained from the illustrated

parts list section(s) of this manual.

OWNER’S MANUAL

Information About the Sprayer

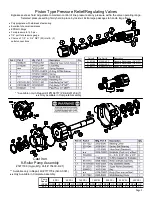

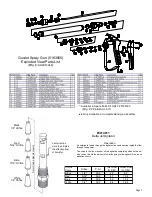

Roller pumps are positive displacement pumps, which means

that the entire solution being pumped must go somewhere or

the pump will break. In this roller pumping system, solution is

drawn from the tank and forced to a planned source, such a

handgun. The pressure is controlled by a pressure relief valve,

which is a spring-loaded device that controls the amount of

fluid bypassed (recirculated) to the tank. The gray adjusting

cap is to be tightened to increase pressure and loosened to

decrease pressure.

NOTE:

Add proper oil to the engine crankcase and gasoline to the

gas tank. Always check the oil in the gear box. Remove the

plug on the side, oil should be visible. Add oil through the top

plug. Refer to the engine manual for the correct type and

amount.

It is important to test the sprayer with plain water before actual

spraying is attempted. This will enable you to check the spray-

er for leaks in the plumbing system.