CP355 Plug-in Addressable Ionization Sensor

Installation and Maintenance Instructions

GENERAL DESCRIPTION

This sensor must be installed in compliance with the control panel system installation manual. The installation must meet the requirements of the

Authority Having Jurisdiction (AHJ). Sensors offer maximum performance when installed in compliance with the National Fire Protection Association

(NFPA); see NFPA 72.

Model CP355 intelligent ionization sensor uses a state-of-the-art sensing chamber. This sensor is designed to provide open area protection and is intend-

ed for use with compatible control panels only.

Two LEDs on each sensor light to provide a local, visible sensor indication. Remote LED annunciator capability is available as an optional accessory

(Part No. RA400Z).

The CP355 requires compatible addressable communications to function properly. Connect this sensor to listed-compatible control panels

only.

SPECIFICATIONS

Operating Voltage Range:

15 to 32 VDC

Max. Avg. Standby Current:

300µA @ 24 VDC (one communication every 5 sec. with LED blink enabled)

Max. Alarm Current (LED on):

6.5 mA @ 24 VDC

Operating Humidity Range:

10% to 93% Relative Humidity, noncondensing

Operating Temperature Range

0° to 49°C (32° to 120°F)

Height:

1.7 inches (43 mm) installed in B350LP Base

Diameter:

6.1 inches (155 mm) installed in B350LP Base

Weight:

3.6 oz. (102 g)

SPACING

Fire•Lite recommends spacing sensors in compliance with

NFPA 72. In low air flow applications with smooth ceilings,

space sensors 30 feet apart. For specific information regard-

ing sensor spacing, placement, and special applications, refer

to NFPA 72 or the System Smoke Detector Application Guide,

available from Fire•Lite.

WIRING GUIDE

All wiring must be installed in compliance with the National

Electrical Code, applicable local codes, and any special

requirements of the Authority Having Jurisdiction. Proper wire

gauges should be used. The installation wires should be color-

coded to limit wiring mistakes and ease system trouble-shoot-

ing. Improper connections will prevent a system from respond-

ing properly in the event of a fire.

Remove power from the communication line before installing sensors.

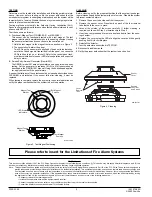

1. Wire the sensor base (supplied separately) per the wiring diagram, see Figure 1.

2. Set the desired address on the sensor address switches, see Figure 2.

3. Install the sensor into the sensor base. Push the sensor into the base while turning it clockwise to secure it in place.

4. After all sensors have been installed, apply power to the control unit and activate the communication line.

5. Test the sensor(s) as described in the TESTING section of this manual.

Dust covers provide limited protection against airborne dust particles during shipping. Dust covers must be removed before the sensors can sense

smoke. Remove sensors prior to heavy remodeling or construction.

6. Tamper-Resistance

Model CP355 includes a tamper-resistant capability that prevents its removal from the bracket

without the use of a tool. Refer to the base manual for details on making use of this capability.

7. After all sensors have been installed, apply power to the system.

8. See Figure 3. Test the sensor by positioning a test magnet against the sensor plastic in the

magnet test area. The alarm level should be recognized at the panel and the LED controlled by

communication command from the panel.

9. Reset the sensor by communication command from the panel.

CAUTION

F300-23-00

1

I56-1970-00R

Fire•Lite, One Fire•Lite Place, Northford, CT 06472-1653, (203) 484-7161

3

2

1

3

2

1

3

2

1

+

-

-

+

UL LISTED COMP

A

TIBLE

CONTR

OL P

ANEL

CLASS A OPTIONAL WIRING

REMOTE ANNUNCIATOR

+

-

CAUTION: Do not loop wire under terminal 1 or 2.

Break wire run to provide supervision of connections.

Figure 1.

Breakaway Stop

9

10

11

12

13

14

15

8

7

6

5

4

3

2

1 0

9

8

7

6

5

4

3

2

1 0

Figure 2.