PRODUCT OVERVIEW

PRODUCT APPLICATION:

The Firex Series Duct Smoke Detectors provide early detection of smoke and products of combustion present in the air moving through an HVAC

duct in commercial, industrial and residential applications.

These devices are designed to prevent the recirculation of smoke in areas by the air handling systems, fans and blowers. Complete systems

may be shut down in the event of smoke detection.

NOTE

For the correct installation of a duct smoke unit, please refer to the NFPA 72E (Standard for Automatic Fire Detectors) and NFPA 90A (Standard

for Installation of Air Condition and Ventilation Systems.)

This detector is not intended for open area protection nor should it be used for early warning detection or replace a regular fire detection system.

Maple Chase provides a special U.L. 50 listed, NEMA 3R rated weatherproof enclosure separately (Model 555) which should be used in

appropriate outdoor applications for protection from the elements. Other installations above the roof line (attics, banjo type roofs, etc.) do not

require the special Model 555 weatherproof enclosure as long as the Maple Chase duct smoke detectors are not exposed to dripping water or

other environmental elements. The Model 555 weatherproof enclosure should be used in all applications where environmental elements are a

concern or local code requires a weatherproof enclosure for proper installation. All installations of our duct smoke detectors and weatherproof

enclosures should be done in accordance with all applicable electrical and building codes.

PRODUCT DESCRIPTION:

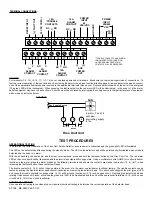

The Firex Smoke Detector is fitted with a mounting base that will accept an Ionization Detector Head Model # 2850-450 or Photoelectric Detector

Head Model # 2850-550. The duct unit supports 2 sets of form “C” and 1 form “A” Alarm Contacts and 1 form “C” Trouble Contact. The trouble

contact supervises the presence of the input power and removal of the detector head.

THE TROUBLE CONTACTS (TERMINALS 4-15-5) ARE SHOWN IN THE NON-ENERGIZED CONDITION.

The trouble contact

will not

operate in the event of a smoke alarm.

The Firex Duct Detector models 2650-760 and 2650-761 will operate on one of the following input voltage sources: 24VAC, 24VDC, 115VAC

and 230VAC.

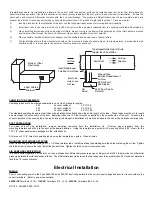

The duct smoke detector units are designed to operate in duct widths from 12 inches to 10 feet wide with an air velocity between 300 and 4,000

feet per minute. To verify correct installation, the pressure differential between the input and exhaust tubes should be measured using a

Magnehelic pressure gauge or equivalent. An acceptable reading must be between 0.01 and 1.2 inches of water.

For a Duct Smoke Detector unit to operate correctly, it must be installed 6 duct widths from any obstruction i.e. elbows, deflector plates, filters,

dampers, etc. In situations where the criteria cannot be met, deviations are acceptable providing they meet the pressure differential

requirements.

SAMPLING TUBES:

The principal of operation of a duct detector is based on the Venturi effect. Two tubes extend into the HVAC duct. Air flowing through the duct

is forced into the air intake tube via the air intake holes, and passes over the detector head. The air will be drawn out via the exhaust tube back

into the HVAC duct. (7” exhaust tube provided in the installation kit.)

When the particles of smoke suspended in the air stream reach the alarm threshold of the detector head, the unit will go into alarm.

Duct Unit Installation

DUCT SMOKE LOCATION PRE-REQUISITES:

This guideline contains general information on duct smoke detector installation, but does not preclude the NFPA documents listed. Maple Chase

Company assumes no responsibility for improperly installed duct detectors. To determine the correct installation position for a Firex Duct Smoke

Detector, the following factors must be considered.

1)

A uniform non turbulent airflow of between 300 ft/min to 4,000 ft/min. must be present in the HVAC duct. To determine the duct

velocities examine the engineering specifications that define the expected velocities or use an Alnor model 6000P

velocity/meter (or equivalent).

2)

In order to prevent stratification, duct smoke units, where possible, must be located a minimum of six duct widths down stream

from a source of turbulence i.e. elbows, deflector plates, filters, dampers, and inlets.

MODEL 2650-760 Ionization

MODEL 2650-761 Photoelectric

INSTALLATION INSTRUCTIONS FOR

UNIVERSAL DUCT SMOKE DETECTORS

R

AP 186 MA 2650-760; 01/01