Warranty, Service & Repair

WARRANTY

Flowline warrants to the original purchaser of its products that such

products will be free from defects in material and workmanship under

normal use and service for a period which is equal to the shorter of

one year from the date of purchase of such products or two years from

the date of manufacture of such products.

This warranty covers only those components of the products which

are non-moving and not subject to normal wear. Moreover, products

which are modified or altered, and electrical cables which are cut to

length during installation are not covered by this warranty.

Flowline’s obligation under this warranty is solely and exclusively

limited to the repair or replacement, at Flowline’s option, of the prod-

ucts (or components thereof) which Flowline’s examination proves to

its satisfaction to be defective. FLOWLINE SHALL HAVE NO

OBLIGATION FOR CONSEQUENTIAL DAMAGES TO

PERSONAL OR REAL PROPERTY, OR FOR INJURY TO ANY

PERSON.

This warranty does not apply to products which have been subject to

electrical or chemical damage due to improper use, accident, negli-

gence, abuse or misuse. Abuse shall be assumed when indicated by

electrical damage to relays, reed switches or other components. The

warranty does not apply to products which are damaged during ship-

ment back to Flowline’s factory or designated service center or are

returned without the original casing on the products. Moreover, this

warranty becomes immediately null and void if anyone other than

service personnel authorized by Flowline attempts to repair the defec-

tive products.

Products which are thought to be defective must be shipped prepaid

and insured to Flowline’s factory or a designated service center (the

identity and address of which will be provided upon request) within

30 days of the discovery of the defect. Such defective products must

be accompanied by proof of the date of purchase.

Flowline further reserves the right to unilaterally wave this warranty

and to dispose of any product returned to Flowline where:

a. There is evidence of a potentially hazardous material present

with product.

b. The product has remained unclaimed at Flowline for longer than

30 days after dutifully requesting disposition of the product.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND

THE DESCRIPTION ON THE FACE OF THIS WARRANTY. This

warranty and the obligations and liabilities of Flowline under it are

exclusive and instead of, and the original purchaser hereby waives, all

other remedies, warranties, guarantees or liabilities, express or

implied. EXCLUDED FROM THIS WARRANTY IS THE IMPLIED

WARRANTY OF FITNESS OF THE PRODUCTS FOR A

PARTICULAR PURPOSE OR USE AND THE IMPLIED

WARRANTY OF MERCHANT ABILITY OF THE PRODUCTS.

This warranty may not be extended, altered or varied except by a writ-

ten instrument signed by a duly-authorized officer of Flowline, Inc.

To register your product with the manufacturer, fill out the enclosed

warranty card and return it immediately to:

Flowline Inc.

10500 Humbolt Street

Los Alamitos, CA 90720.

If for some reason your product must be returned for factory service,

contact Flowline Inc. to receive a Material Return Authorization

number (MRA) first, providing the following information:

1. Part Number, Serial Number

2. Name and telephone number of someone who can answer

technical questions related to the product and its application.

3. Return Shipping Address

4. Brief Description of the Symptom

5. Brief Description of the Application

Once you have received a Material Return Authorization number,

ship the product prepaid in its original packing to:

Flowline Factory Service

MRA _____

10500 Humbolt Street

Los Alamitos, CA 90720

To avoid delays in processing your repair, write the MRA on the

shipping label. Please include the information about the malfunc-

tion with your product. This information enables our service tech-

nicians to process your repair order as quickly as possible.

®

Version 1.6A

© 2005 FLOWLINE Inc.

All rights reserved.

Manual # LO900002 - 0208-PS1M1_6A

NRTL/C

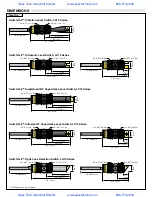

Switch-Tek™

Powered Level Switches

LZ12, LU10, LP15,

LP10, and LO10 Series

Owner’s Manual

I P

68

Spec Tech Industrial Electric www.spectechind.com

888-773-2832

Spec Tech Industrial Electric www.spectechind.com

888-773-2832