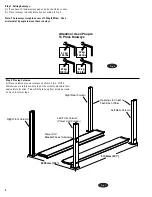

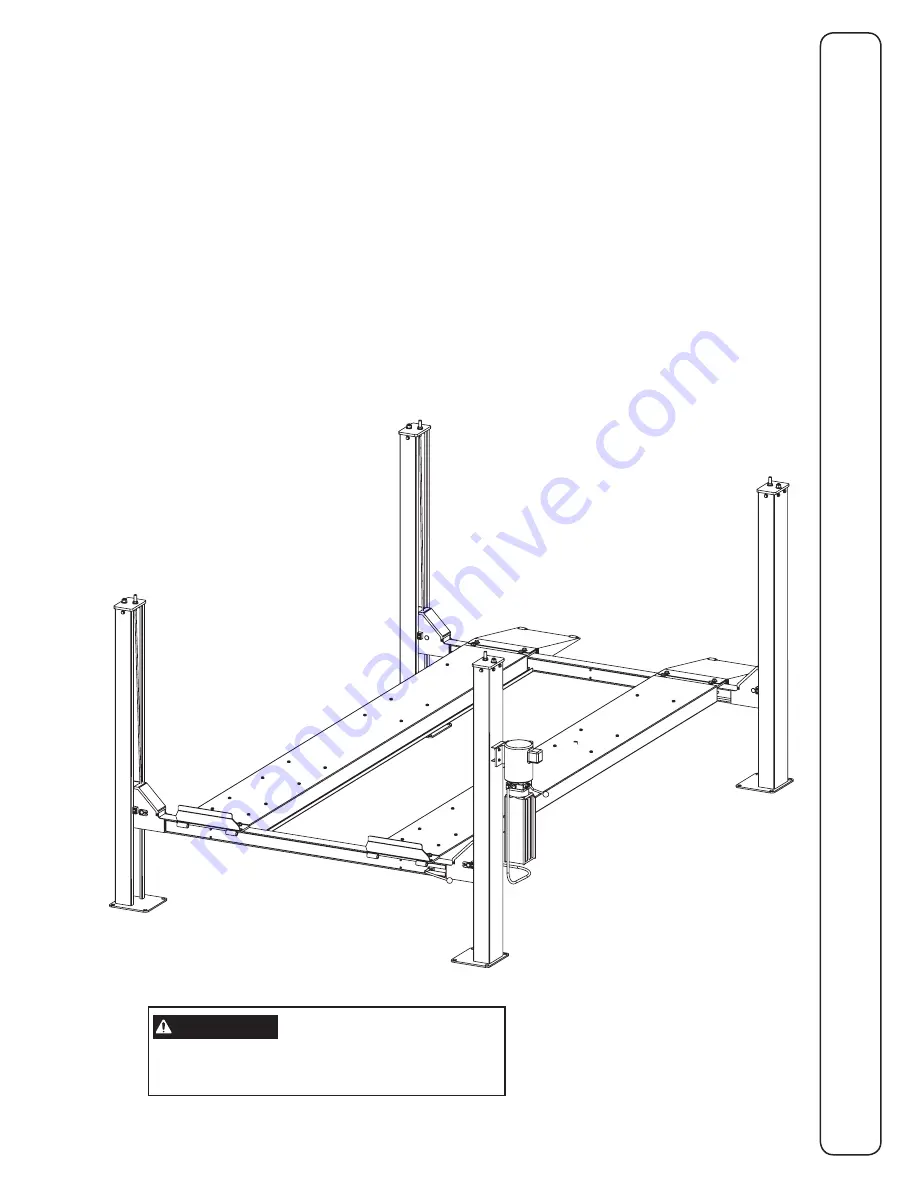

RSM4T

Capacity 4082 kg (9000 lbs)

2041kg (4500 lbs) per axle

Maximum Wheelbases: 3861mm (152")

Minimum Wheelbase At Rated Capacity: 2515mm (99")

IN20534

Rev. C 9/10/2010

© September 2012 all rights reserved.

CO8347

I

N

S

T

A

L

L

A

T

I

O

N

I

N

S

T

R

U

C

T

I

O

N

S

I

N

S

T

A

L

L

A

T

I

O

N

I

N

S

T

R

U

C

T

I

O

N

S

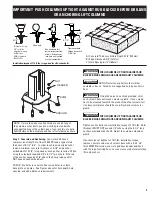

IMPORTANT

Reference ANSI/ALI ALIS,

Safety Requirements for

Installation and Service of Automotive Lifts

before installing lift.