USA 1-800-374-4432

www.frigidaire.com

Canada 1-800-265-8352

www.frigidaire.ca

316495194

Important Safety Instructions ............................... 3

List of materials ................................................... 5

Electrical requirements ......................................... 5

Location requirements .......................................... 6

Product dimensions .............................................. 6

Venting Requirements .......................................... 7

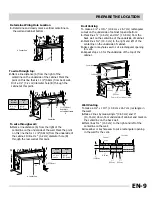

Prepare the location ............................................. 8

Install Range Hood (Ducted version) ..................... 10

Make Electrical Connection .................................... 11

Range Hood Use .................................................. 12

Range Hood Care ................................................. 13

Troubleshooting ................................................... 15

Warranty Information ........................................... 16

August 2016