WARNING

THE COMPORNENTS IDENTIFIED BY THE MARK

“

”

ON THE SCHEMATHIC

DIAGRAM AND IN THE PARTS LIST ARE CRITICAL FOR SAFETY.

PLEASE REPLACE ONLY BY THE COMPORNENTS SPECIFIED ON THE SCHMATHIC

DIAGRAMAND IN THE PARTS LIST.

IF YOU USE WITH PART NUMBER UN-SPECIFIED, IT MAY RESULT IN A FIRE AND AN

ELECTORICAL SHOCK.

FUJI PHOTO FILM CO.,LTD.

Ref.No.:ZM00438-10

5

Printed in Japan 2002.06(T.S.)

U/E-Model

SERVICE MANUAL

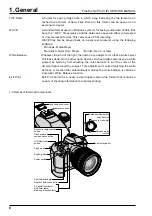

FinePix S2 Pro

DIGITAL CAMERA