Mounting and Operating Instructions for

Powered Auxiliary Outboard Motor

Brackets Models 71095 and 71096

Form 12.441

Thank you for choosing the Garelick/EEz-In Brand. The

design/technology found in features of this product represent

over 25 years of auxiliary outboard motor bracket experience

and the fourth generation of brackets offered by our company

to the boating public.

We are proud to manufacture this product to help you enjoy

your time on the water. If you would like to comment on your

experiences, please feel free to contact us by e-mail or write a

letter to our Customer Service Center. When contacting us,

please provide the serial number, which gives us the date of

manufacture.

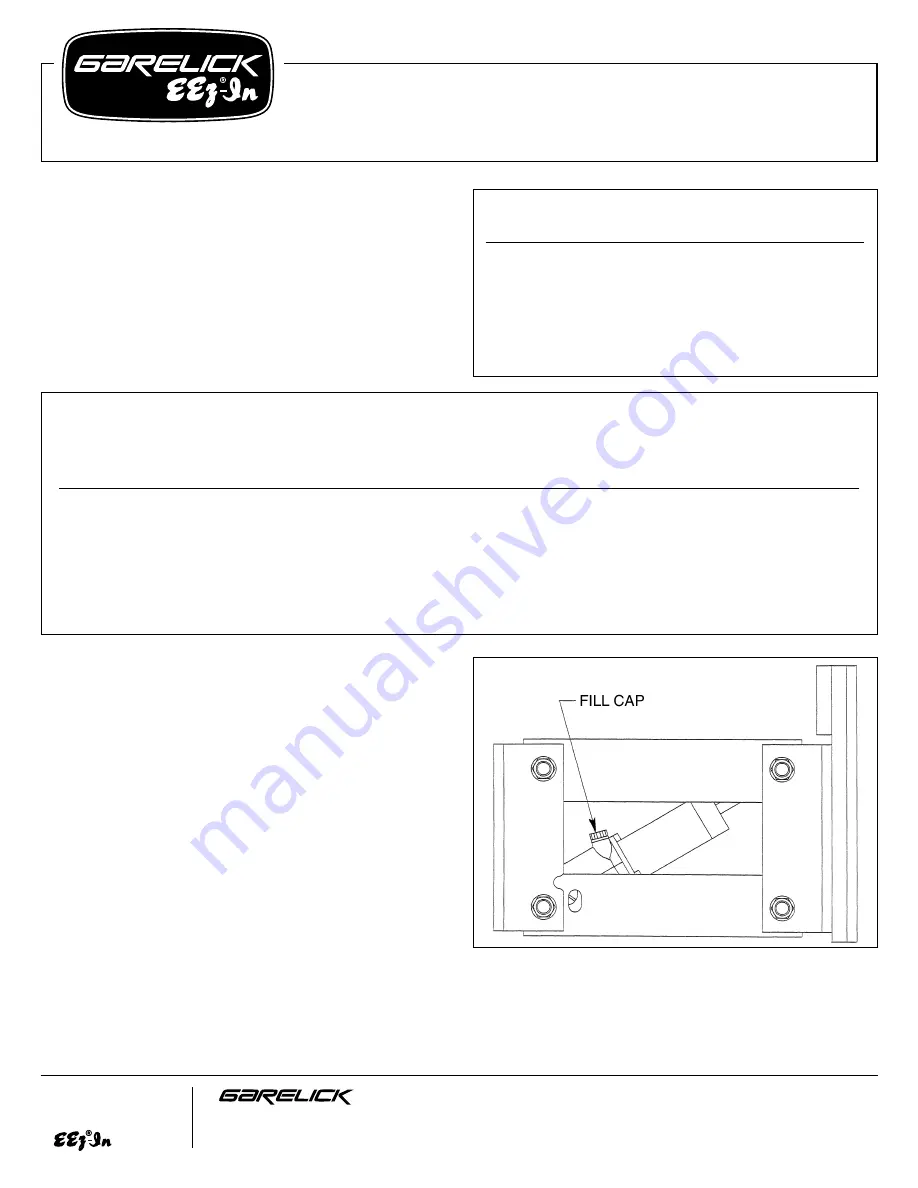

FIG. 1

Write for

a Complete

Catalog

Phone: 651-459-9795

PO Box 8, 644 2nd Street

E-mail: mail@garelick.com

St. Paul Park, Minnesota 55071

On the Web: www.garelick.com

10/01

SUPPLIED HARDWARE:

Part No.

Quantity

Description

49.274

0

1 each

electrical harness with operating switch

03.412

4 each

1/2–20 x 4-1/2” stainless steel bolts

03.413

4 each

1/2” x 1-1/2” stainless steel washers

03.414

4 each

1/2” x 7/8” stainless steel washers

03.411

4 each

1/2–20 brass locknuts

MOUNTING INSTRUCTIONS

Note:

The approximate vertical travel of the 71095/71096 Motor

Brackets is 13”. This travel is based on installation that’s

perpendicular to the water surface. The vertical travel will be less

than 13” if the installation is on a positive angled transom, and will

be more than 13” if installed on a negative angled transom. If your

transom angle is more than 10° out of perpendicular, we

recommend fabricating a wedged spacer out of a suitable material

such as starboard, aluminum or finished hardwood to allow your

installation to be perpendicular to the water surface.

Failure to

follow these instructions can cause the actuator to retract below

a horizontal position. This may cause the pump to draw air and

fail to return to a stowed position.

The outside dimensions should

be a minimum of 5-1/2" x 11-1/2", one for each mounting angle,

or a single piece 11-1/2" x 20-1/2".

1. The Motor Bracket is shipped in the mid-stroke position. To

complete installation, it is necessary to activate the Bracket

to full down position. Set the Bracket on a flat surface. With

a standard 12 volt battery, connect the green cable to the

positive terminal and the blue cable to the negative

terminal. This will cause the hydraulic cylinder to retract to

SPECIFICATIONS

H.P. Rating

Motor Weight

Vertical

Mounting

Mounting Board

Mounting Bracket

Not to Exceed

Travel

Pad

Dimensions

Dimensions

W x H x T

W x H

71095

Up to 25

148 lbs.

13-1/4”

poly/alum

15-3/4” x 14” x 2”

12-1/4” x 8”

(33 cm)

(40 x 35 x 5 cm)

(31 x 20 cm)

71096

25 to 40

248 lbs.

13-1/4”

poly/alum

15-3/4” x 14” x 2”

16-1/4” x 8”

(33 cm)

(40 x 35 x 5 cm)

(41 x 20 cm)

Triple coat protective finish (anodized, E-Coat, powder coated).

1

its shortest length or closed position. This is the full down

position for the motor bracket. Disconnect the negative

cable followed by the positive cable. (See Figures 1 and 2)

(continued)