Reviews:

No comments

Related manuals for Approach G5 - GPS-Enabled Golf Handheld

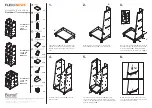

TSID-72-6

Brand: True Pages: 2

Flexi-News Series

Brand: Bartuf Pages: 2

MUZA

Brand: UBC Pages: 52

BFI57

Brand: F.u.n.k.e. Pages: 40

AK-950 Series

Brand: Ameri-King Pages: 38

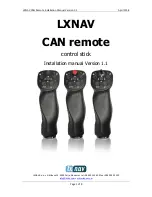

CAN remote

Brand: LXNAV Pages: 9

tailBeacon TSO

Brand: uAvionix Pages: 36

6423

Brand: Nemco Pages: 2

45514502

Brand: Nordcap Pages: 19

Panorama 550L

Brand: Bartscher Pages: 17

TSID-48-4

Brand: True Pages: 2

TSID-48-2-L

Brand: True Pages: 2

TSID-48-2

Brand: True Pages: 2

TSID-36-4

Brand: True Pages: 2

TSID-36-2

Brand: True Pages: 2

TDBD-96-6

Brand: True Pages: 2

TDBD-48-4

Brand: True Pages: 2

TDBD-72-2

Brand: True Pages: 2