Index

Contexts

................................................................ ………….

Chapter – Page

1

Safety

........................................................................….............…………..…….1 - 1

1

.01

Directives..........................……..................…......................................……..…...1 - 1

1

.02

General notes on safety.........................…….….....................................………..1 - 1

1

.03

Safety symbols.................................................................................……….…… 1 - 2

2

Proper use

……............................................................................…….....…...... 2 - 1

3

Specifications

………......................................................................……........... 3 - 1

3

.01

GP-710-148, GP-724-108.......................................…....................................…. 3 - 1

3

.02

Needles and threads …………...................................................…...…..........…. 3 - 2

3

.03

Possible models and subclasses ………..........................................…..........….. 3 - 2

4

Explanation of symbols

……………...…........................................................... 4 - 1

5

Controls

……….................................................................................................. 5 - 1

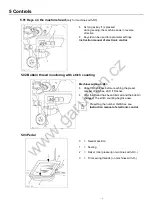

5.

01

Keys on machine head (only for machines with -D3/.. ) …………....................... 5 - 1

5.

02

Bobbin thread monitoring with stitch counting ………….............…..................... 5 - 2

5.

03

Pedal …......................................................................…....….............................. 5 - 2

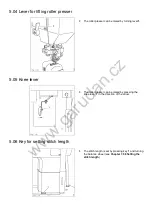

5.

04

Lever for lifting roller presser …………........................……................................. 5 - 3

5.

05

Knee lever .................................................................…...................................... 5 - 3

5.

06

Dey for seeting stitch length ……….................................................................. 5 - 4

5.

07

Swing out roller presser ............................…..............................…..................... 5 - 4

6

Installation and commissioning

...................……………..........….........……... 6 - 1

6

.01

Installation..................................……................................….............................. 6 - 1

6

.01.01

Adjusting the table height.............................................…...…..............…......…. 6 - 1

6

.02

Fitting the reel stand ...........................………….............................…................. 6 - 2

6

.03

Tilted work base ..................................……................................…….............…. 6 - 3

6.

04 Table top cutout ......................……..…............................................................ 6 - 4

6

.05

Mounting the table top...............……………...............................…..................... 6 - 5

7

Preparation.

........................................................…............................................ 7 - 1

7

.01

Inserting the needle on model GP-710…............................................................ 7 - 1

7

.02

Inserting the needle on model GP-724........................…………......................... 7 - 2

7

.03

Winding the bobbin thread; adjusting the bobbin thread tension .........…........... 7 - 3

7

.04

Removing/Inserting the bobbin case .......………………….................................. 7 - 4

7

.05

Threading the bobbin case/Adjusting the bobbin thread tension ..................... 7 - 4

7

.06

Threading the needle thread and regulating its tension on model GP-710……....7 - 5

7

.07

Threading the needle thread and regulating its tension on model GP-724......... 7 - 6

7

.08

Setting the stitch length ....................................................……….................…... 7 - 7

8

Care and maintenance ..

.....................................………........…..................… 8 - 1

8.

01

Checking/adjusting the air pressure....................................................................8 - 1

8.

02

Cleaning the air filter of the air-filter/lubricator............... ...............................…..8 - 2

8.

03

Cleaning ...............................................…......................…................................ 8 - 3

8.

04

Oiling the hook ....................…....................…................................................... 8 - 4

8.

05

Oil bowl for hook lubrication....….…….....……………………....…….................. 8 - 4

8.

06

Filling the oil reservoir of the thread lubrication unit ..............………................. 8 - 5

8.

07

Lubricating the bevel gears ............................................…………..................... 8 – 6

9

Adjustment

..............................………............................................................... 9 - 1

9.

01

Notes on adjustment............................…............................................................ 9 - 1

www.garudan.cz