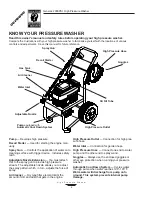

2000PSI

The Reliable Ones

High Pressure Washer

Owner’s Manual

Problems?

Questions?

Before t

aking your unit

back to the store,

call the pressure washer

helpline at

1-800-270-1408

M-F 8-5 CST

This pressure

washer is

equipped with an

Automatic Cool

Down System.

See page 11 for

details

GENERAC

This symbol points out important safety instructions, which, if not followed, could endan-

ger the personal safety and/or property of yourself and others. Read and follow all

instructions in the manual before attempting to operate this unit.

Model No. 10400 (2000 PSI High Pressure Washer) Manual No. B2062 Revision 1 (3/8/98)