Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

2000225228A.11.03

All replacement parts

All labour charges

All call-out charges

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

to offer our customers' a Comprehensive First Year Guarantee.

In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and

return as soon as possible.

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Service number 01773 828100.

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

Guarantee Registration

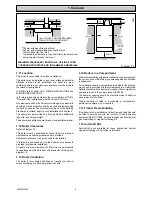

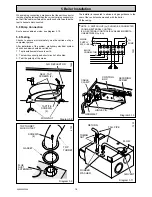

Fanned Flue Boiler

This is a Cat I

2H

Appliance

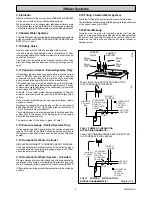

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

For Ireland the current edition of I.S.813

"Domestic Gas Installations" must be used.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

T o b e l e f t w i t h t h e u s e r

7319

❏

✔

❏

✔

❏

✔

Instructions for Use

Installation and Servicing

G.C. No. 41-047-49

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0208 247 9857

Micron

60FF