Operation

Reactor® E-30i and E-XP2i

3A1705E

EN

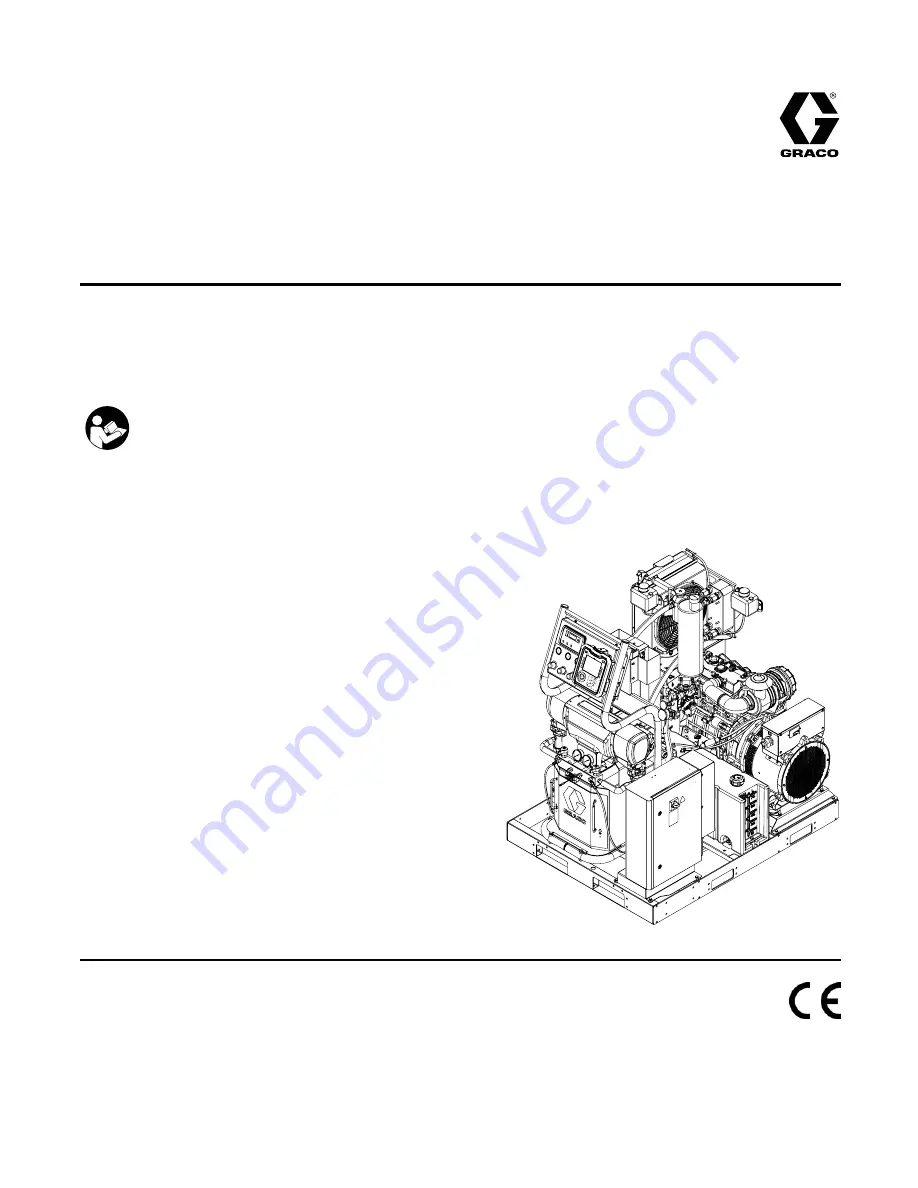

Electric, Heated, Integrated Plural Component Proportioning System With Integrated Generator. For

spraying polyurethane foam and polyurea coatings. For professional use only. Not approved for use in

explosive atmospheres or hazardous locations.

Important Safety Instructions

Read all warnings and instructions in this manual. Save these

instructions.

PROVEN QUALITY. LEADING TECHNOLOGY.

Summary of Contents for 259079

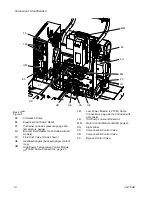

Page 34: ...Setup A5 A1 A2 AS AN A3 AT A3 A4 A2 A6 A4 34 3A1705E...

Page 45: ...Advanced Display Module ADM Operation Setup Screens Navigation Diagram Figure 35 3A1705E 45...

Page 49: ...Advanced Display Module ADM Operation Run Screens Navigation Diagram Figure 36 3A1705E 49...

Page 93: ...Dimensions Dimensions Top View Figure 43 Side View Figure 44 3A1705E 93...

Page 95: ...Dimensions Pallet Mounting Dimensions Figure 48 3A1705E 95...

Page 97: ...Notes Notes 3A1705E 97...