Operation, Repair, and Parts

EcoQuip

EcoQuip

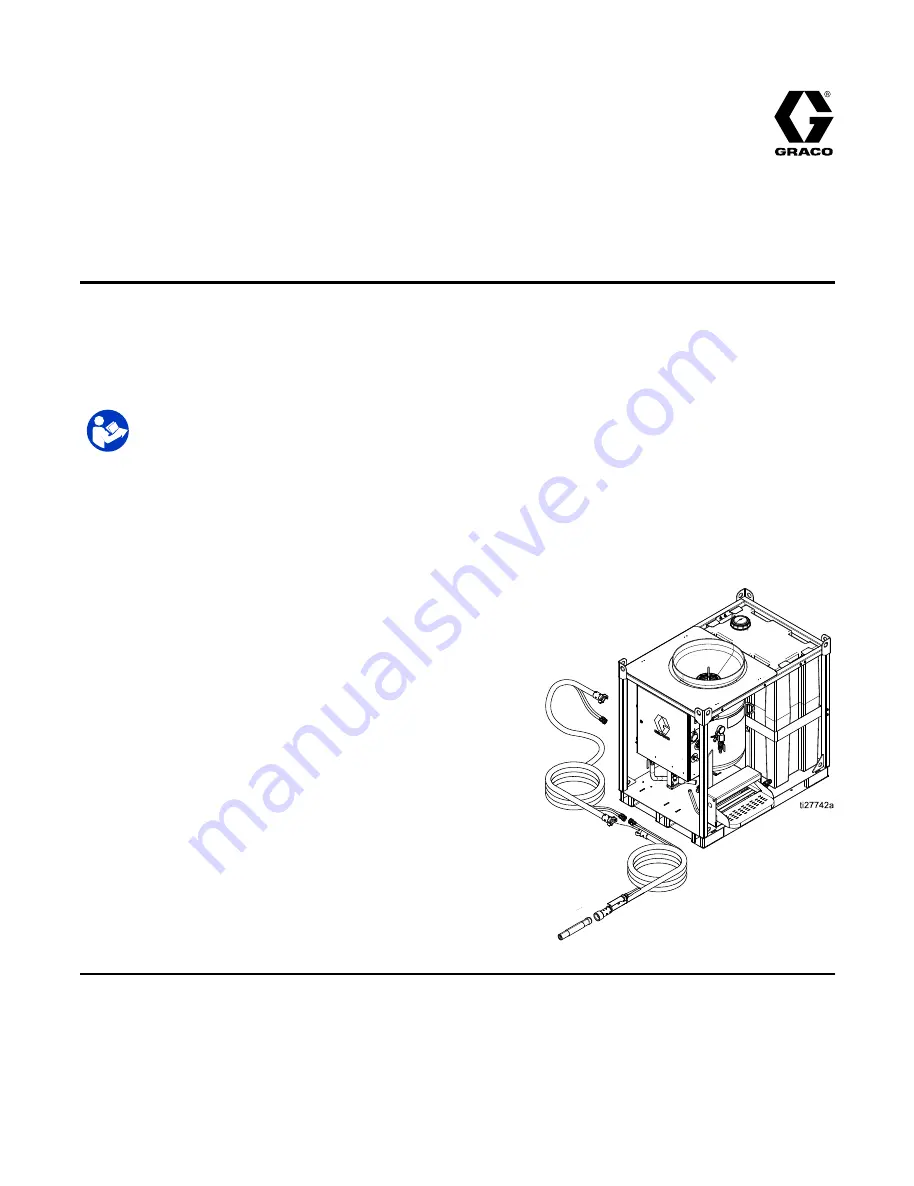

EcoQuip 2™

2™

2™ Vapor

Vapor

Vapor Abrasive

Abrasive

Abrasive Blast

Blast

Blast

System

System

System

3A3489E

EN

Vapor

Vapor

Vapor abrasive

abrasive

abrasive blast

blast

blast system

system

system for

for

for coating

coating

coating removal

removal

removal and

and

and surface

surface

surface preparation.

preparation.

preparation. For

For

For professional

professional

professional use

use

use only.

only.

only.

Important

Important

Important Safety

Safety

Safety Instructions

Instructions

Instructions

Read all warnings and instructions in this manual. Save these

instructions.

175 psi (12.06 bar, 1.2 MPa) Maximum

Working Pressure

See page 3 for Models and approval

information.

PROVEN QUALITY. LEADING TECHNOLOGY.

All manuals and user guides at all-guides.com

all-guides.com