Owner’s Manual

HK3819 / HK5523

Page 1

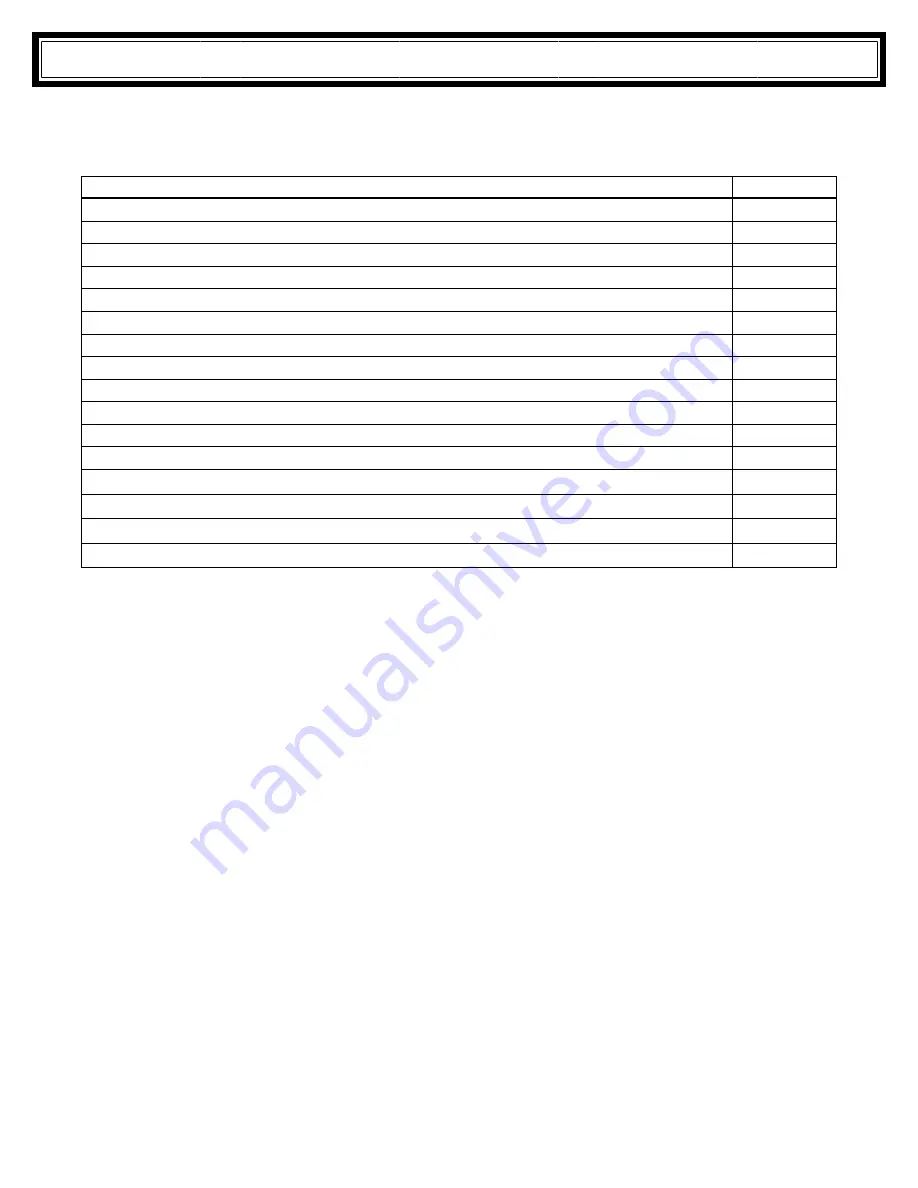

TABLE OF CONTENTS

Warranty Information

2

Important Safety Precautions

3

Introduction

4

Set Up, Priming, Spraying

5

Flushing & Priming

5

Shut Down and Pressure Relief Procedures

6

Airless Spray Painting Suggestions

7-8

Tip Selection

8-9

Troubleshooting

9

Repair Procedures

10-11

Piston Cartridge Assembly Repairs

12-13

Pressure Control Calibration

14

Prime Valve Service

14-15

Unit Parts Breakdown

16

Cart Parts Breakdown

17

Wiring Schematic

18

Parts List and Descriptions

19-22