Summary of Contents for AMTAX sc

Page 2: ......

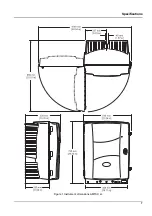

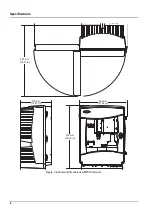

Page 7: ...7 Specifications Figure 1 Instrument dimensions AMTAX sc...

Page 12: ...12 General Information...

Page 36: ...36 System Start Up...

Page 44: ...44 Operation...

Page 56: ...56 Maintenance...

Page 64: ...64 Troubleshooting...

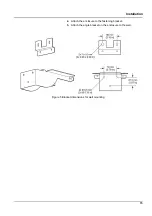

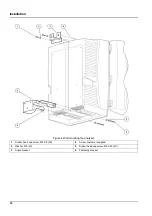

Page 69: ...69 Replacement Parts and Accessorie Figure 23 Analyzer enclosure AMTAX indoor sc...

Page 70: ...70 Replacement Parts and Accessorie Figure 24 Analyzer panel overview...

Page 71: ...71 Replacement Parts and Accessorie Figure 25 Analyzer panel front view details...

Page 72: ...72 Replacement Parts and Accessorie Figure 26 Analyzer panel back view details...

Page 76: ...76 Warranty and liability...