INTRODUCTION

This flanged, industrial refrigeration duty solenoid

valve is ver y simple and compact but rugged in

construction. Body is plated steel alloy with a

direct lifting stainless steel plunger that contains

a teflon seat that closes on a stainless steel

orifice. When electrically energized, seat opens

wide; when de-energized, it closes to stop flow

in the arrow direction on the valve body.

APPLICATIONS

This small, direct lifting valve is used primarily

as a pilot for various larger gas-powered or

liquid powered main valves, as a remote pilot

for back pressure regulators or other devices,

or as a liquid stop valve for expansion valves,

float valves, or as a general purpose pilot line for

ammonia, R22, R134a, CO2 and other approved

refrigerants or oil.

MAXIMUM RATINGS, AMMONIA

Liquid, Receiver Pressure: 15 Tons (52 kW)

Flow Factor: Cv=0.41 (Kv=0.35)

ADDITIONAL FEATURES

Encapsulated Hansen standard coil

300 psi (20 bar) MOPD

Available close-coupled strainer

Heavy-duty, direct lift

CSA Certified Status

Non-asbestos gaskets

KEY FEATURES

MATERIAL SPECIFICATIONS

Body: Steel, plated

Solenoid Tube: Stainless steel

Plunger: Stainless steel

Seat Orifice: Stainless steel

Seat: Teflon

Safe Working Pressure: 400 psig (27 bar),

600 psig (40 bar) available for CO2

Operating Temperature: -60ºF to 240ºF

(-50ºC to 115ºC)

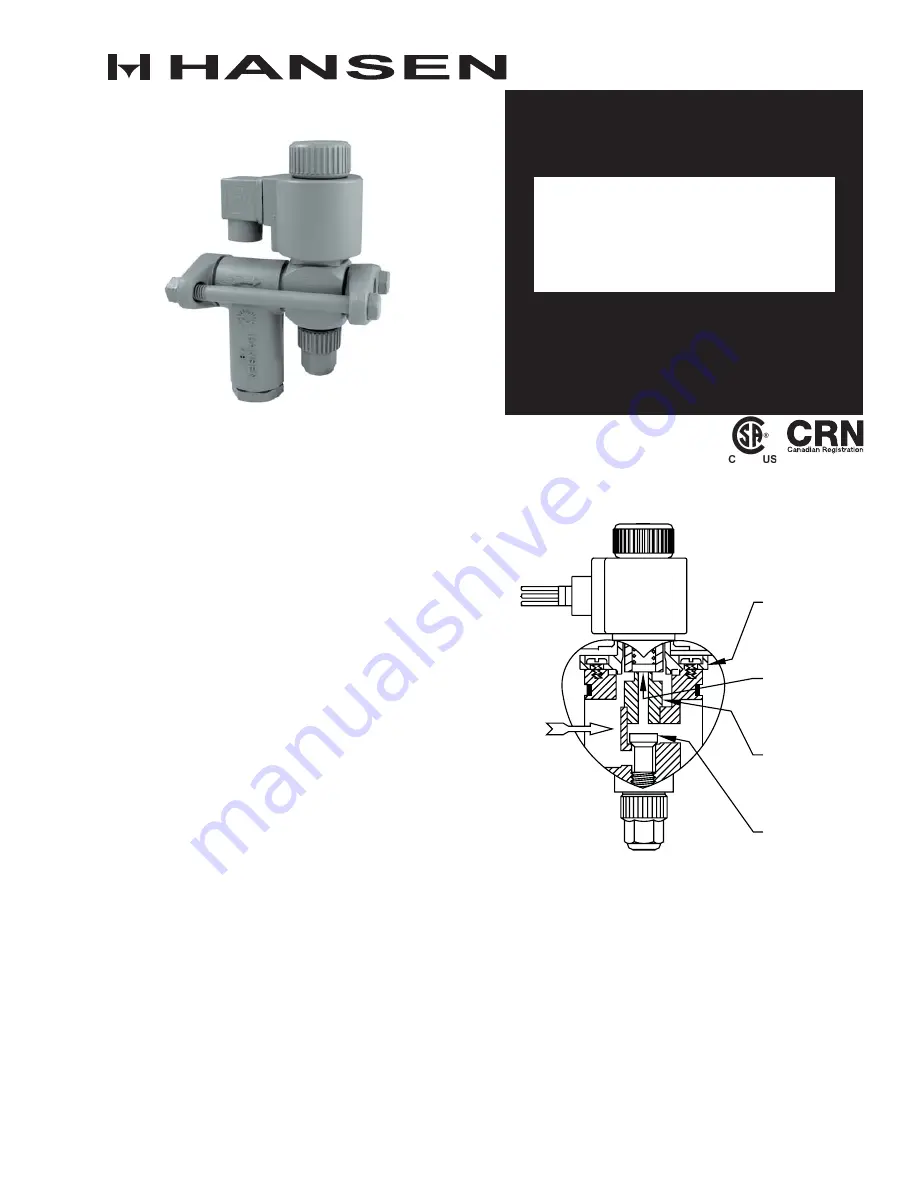

REMOVABLE

SOLENOID TUBE

TEFLON DISC

STAINLESS STEEL

SEAT

MANUAL OPENING

STEM

Specifications, Applications,

Service Instructions & Parts

HS6

SOLENOID VALVE

5/32” (4 mm) PORT

Bulletin S117c

MAR 2006

Flanged

1/4” thru 3/4”

(7 mm thru 20 mm)

for refrigerants

HS6 Solenoid Valve

with Close-Coupled ST050 Strainer