N15W24983 Bluemound Rd. • Pewaukee, WI 53072 USA

Tel: 262-691-3320, Fax: 262-701-5780 • Web: www.harken.com, Email: harken@harken.com

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury,

or death. See www.harken.com/manuals for additional safety information.

Replacement Loops

Part

No.

Description

Sheave

Ø

Max line

Ø

Maximum

working load

Breaking

load

in

mm

lb

kg

lb

kg

2148

40 mm single

40 mm

3

/

8

10

485

220

1200

544

2151

57 mm single

57 mm

7

/

16

10

792

359

2380

1080

Specifications

Terms

Planning Installation

Loop only to objects with rounded edges. Avoid sharp corners.

WARNING! Loop can easily be cut on sharp corners causing it to break suddenly under

load, possibly causing an accident.

Using Alternate Line, Knots, and Splices

WARNING! Failure to account for loss of strength due to chafe or UV damage when choosing

line can result in line breaking suddenly when load is applied.

WARNING! Improper knots or splices can weaken the block installation causing it to break

suddenly when load is applied, possibly causing an accident.

Harken equipment is designed for minimal maintenance. However, some upkeep is required to give

the best service and comply with the Harken limited warranty.

Keep your equipment clean and free-running by frequently fl ushing with fresh water. Periodically

clean with mild detergent and water solution. Spin sheaves to distribute soap solution evenly.

Flush with fresh water.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can result in discolor-

ation of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance, and warranty information: www.harken.com/manuals or the

Harken catalog.

Maintenance

Printed

in

USA 4369 07-20

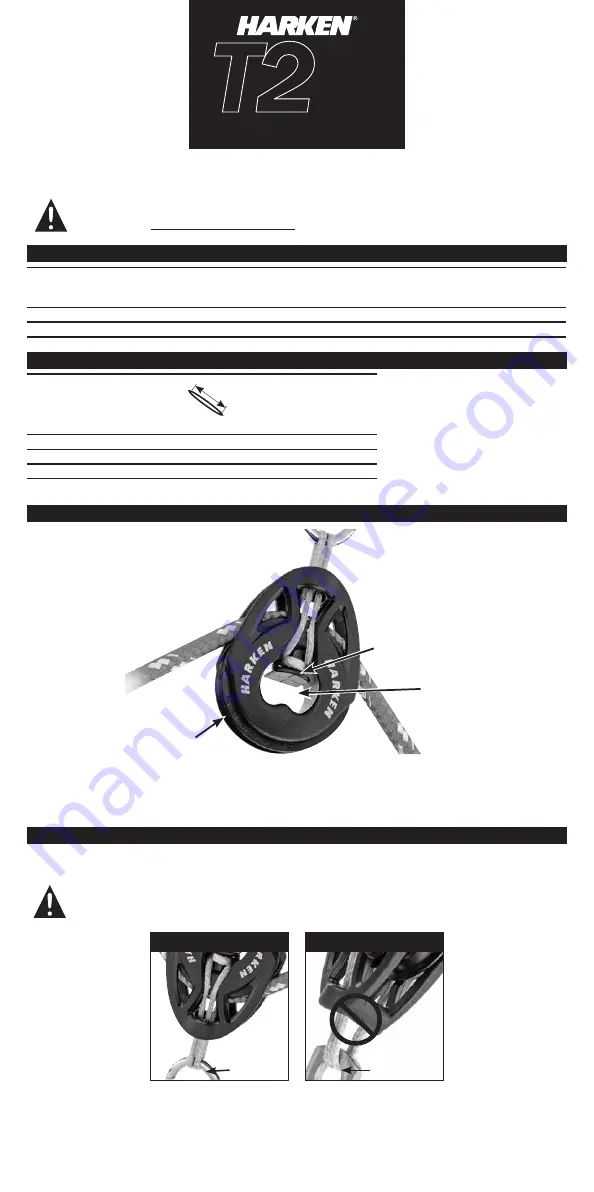

INCORRECT

CORRECT

Rounded

Sharp

Anchor post

Head

Mouth

Sheave

Bail

Loop

Read important information on choosing line, knots, and splices:

www.harken.com/knots.

Additional Information

For additional information go to online manual 4369 at www.harken.com/manuals.

Part No. 2148 (40 mm)

2151 (57 mm)

Strands

lb

kg

lb

kg

4

600

272

1190

540

Minimum breaking load for line to make loop

Four (4)

strands

Part

No.

Fits blocks

Loop

length

Line

type

Loop line

Ø

in

mm

in

mm

2154

2148

5 1/2

140

Spectra

1

/

8

3

2151

2148, 2151

6 1/2

165

Spectra

1

/

8

3

2179

2148, 2151

14 1/2

370

Spectra

1

/

8

3

I N S T R U C T I O N S

Patented

™

LOOP

Dyneema is a registered trademark of DSM Dyneema.

Spectra is a registered trademark of Honeywell International, Inc.

Harken is not liable or responsible for use of line used to secure blocks. Go to

Harken Limited

Warranty

at www.harken.com for complete details. It is your responsibility to choose the correct line

for the block.

When choosing line, use a breaking load that is at least double the block's breaking load to

account for strength loss from:

1. Knots slipping or breaking at a much lower load than line breaking load. Spectra

®

or Dyneema

®

-

type lines require specialized knots.

2. Splices slipping or failing due to incorrect type or execution.

3. UV damage increasing with each passing year.

4. Chafing seriously reducing strength.

If you are not comfortable choosing line, work with a qualified rigger or use Harken-supplied loops

2148 or 2151. Go to www.harken.com/knots for additional information.

Spin sheave

while

cleaning