Please read this leaflet carefully and keep it in a safe

place

POLYSPRAY 2/ WEEDSPRAY

2 PRESSURE SPRAYER

4075/4076

2 pint 1.25 litre

OPERATING INSTRUCTIONS

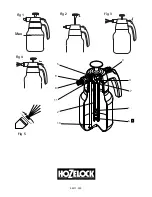

1. Unscrew the container (Figure 1). Fill it to the

maximum (Figure 2). Screw the head assembly unit

firmly into place.

2. Pressurise the sprayer by pumping about 40 strokes

(Figure 3). The sprayer has a built-in device to

prevent over-pressurisation.

3. For small areas ‘Spot Spray’ by depressing the lever

(Figure 4).

4. For larger areas spray continuously by pushing

forward lock-on button (Figure 5).

5. Adjust the nozzle as required (Figure 6). Turn anti-

clockwise for jet, or push in nozzel and turn

clockwise for spray,

6. After a short time, pressure will drop. Restore

pressure by pumping.

7.

After use, release excess pressure by slowly

unscrewing the head assembly. This will allow air to

escape.

8. If you have used chemicals in the sprayer, discard any

unused solution safely. Fill the sprayer with warm

(not hot) water and a little detergent. Spray this

through the unit. Repeat with clean cold water.

Check that the nozzle and the grooves in the nozzle

spindle are free from sediment.

SPRAYING CHEMICALS

This sprayer is intended for water solutions of

proprietary insecticides, fungicides, weed-killers and

foliar feeds.

Follow these instructions carefully.

•

Wear protective clothing, goggles, face-masks and

gloves.

•

Do not inhale spray mist.

•

Avoid skin contact with chemical sprays.

•

Work in a well-ventilated area.

•

Take care to protect children, pets and fish from

exposure to chemicals.

•

Seek medical attention if spray gets in your eyes or if

you develop any symptoms after spraying.

•

Wash your hands thoroughly after using the sprayer,

especially before eating.

•

Wash contaminated clothing.

•

Do not spray over food or food preparation areas.

•

When spraying crops, follow the chemical

manufacturer’s advice on how soon you can pick or

eat the crops after spraying.

•

Do not spray any solvent-based material such as

white spirit.

USING POWDERED CHEMICALS

•

Spray only thin watery solutions. Thicker mixtures

will clog the nozzle.

•

Powdered chemicals that are completely soluble in

water can be sprayed easily. If they are not fully

soluble, and tend to settle, keep shaking the bottle.

•

If the solution contains sediment, strain the liquid

into the sprayer bottle.

CLEANING THE SPRAYER

•

After use, clean thoroughly with warm water and

detergent, then rinse, as in instruction 8. Repeat if

necessary.

NOTE

Your sprayer is made from several different types of

plastic. Even if the liquid you wish to use is packed in a

plastic container, it may damage the sprayer. If you are

in any doubt about the material you intend to spray,

write to our Consumer Services Department at the

address below.

TIPS ON MAINTENANCE

A. Plunger Assembly

Keep the plunger ‘o’ ring lubricated.

To gain access, unscrew the container from the sprayer

head and expose the barrel.

Unscrew and remove the barrel, making sure you do not

displace the ‘o’ ring seal on the thread.

After lubricating, or fitting a new part, replace the

barrel carefully, and ensure that grease does not enter

either of the small holes in the plunger.

B. Replacing the valve seals and springs

Remove:

(1) the pump barrel, as above

(2) the nozzle retaining cap, using a screwdriver

(3) the nozzle.

Raise the pump knob fully.

Lift off the top of the sprayer and also the operating

lever/lock.

You can now get at the springs and valve seals. Remove

the springs and slide the valve backwards.

Always lubricate the seals on re-assembly.

C. Pump non-return valve

To remove the valve, insert a small screwdriver under

the outer edge of the valve, making sure you do not

damage the barrel, and lever it outwards. To re-fit,

position the pip on the back of the valve over the hole

in the bottom of the pump barrel. Snap it in by pushing

the front centre of the valve with a blunt tool.

D. Sealing washer

This is fitted to ensure an airtight seal between the

sprayer head and the container. To check this part, fill

the sprayer with water, pressurise the container, and

turn it upside down. If there is a leak, liquid will be

forced from the joint.

GB