Institutional Series

™

I-20

Gear-Driven Sprinklers

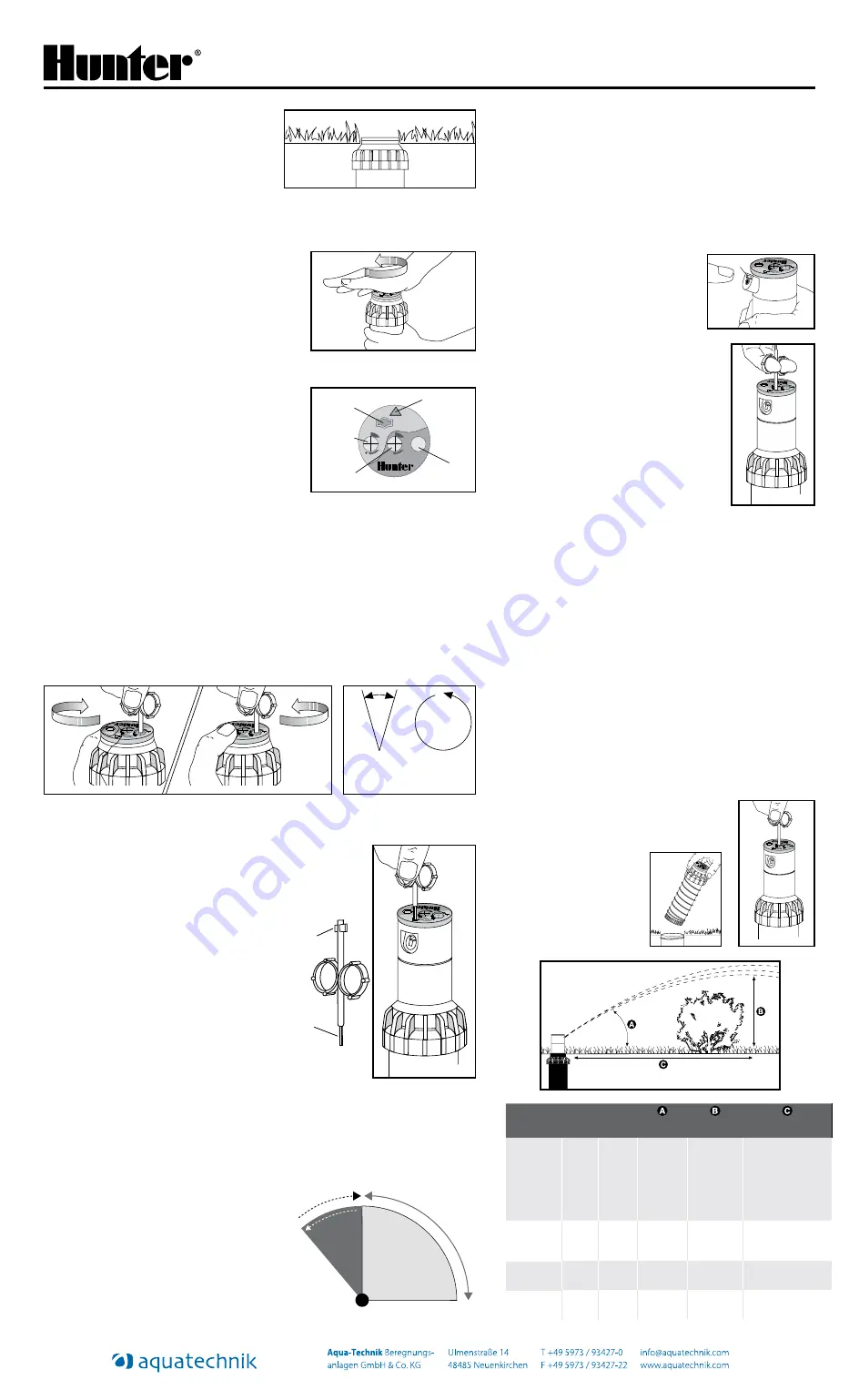

ARC ADJUSTMENT

The I-20 pop-up sprinkler should be

installed at finished grade as shown in the

illustration (Fig. 1).

Arc Adjustments:

Adjustable heads are preset to

approximately 180°. Sprinklers may be adjusted with water on or off. It is

recommended that initial adjustments be made before installation.

1. Using the palm of your hand, rotate the

nozzle turret counterclockwise to the left stop

to complete any interrupted rotation cycle

(Fig. 2).

2. Rotate the nozzle turret clockwise to the

right stop. This is the fixed side of the arc.

The nozzle turret must be held in this

position for arc adjustments. The right stop

does not change.

To Increase the Arc:

1. Insert the plastic key end of the Hunter

wrench into the adjustment socket

(Fig. 3 & 4).

2. While holding the nozzle turret at the right

stop, turn the wrench clockwise. Each full

360° turn of the wrench will increase the

arc 90°.

3. Adjust to any arc between 50° and 360°

(Fig. 5).

4. The wrench will stop turning, or there will be a ratcheting noise, when the

maximum arc of 360° (full-circle) has been reached.

5. When set to 360°, the sprinkler will rotate continually counter-clockwise.

To Decrease the Arc:

1. Insert the plastic key end of the Hunter wrench into the adjustment socket

(Fig. 3 & 4).

2. While holding the nozzle turret at the right stop, turn the wrench counter -

clockwise. Each full 360° turn of the wrench will decrease the arc 90°.

3. Adjust to any arc between 50° and 360° (Fig. 5).

4. The wrench will stop turning, or there will be a ratcheting noise, when the

minimum arc of 50° has been reached.

Fig. 1

Fig. 2

Note:

It is not necessary to disassemble the sprinkler to make adjustments.

Fig. 5

Minimum

Arc

50

°

360

°

Maximum

Arc

Fig. 4

Decrease Arc

Increase Arc

Insert the steel hex end of the Hunter wrench into

the radius adjustment screw (Fig. 6). Turn the screw

clockwise (into the stream of water) to decrease the

radius, or counterclockwise to increase the radius.

Radius can be reduced up to 25%.

Fig. 6

RADIUS / DISTANCE OF THROW

Caution: Turning the adjustment

screw clockwise more than five

full turns may result in a lost radius

adjustment screw.

R EC L AIMED ID

All Hunter rotors are available with

a purple rubber cover permanently

attached. The purple cover shows

that reclaimed water is being used

for the project, which promotes safety on the job site.

S HRU B STA K ING K IT P/ N 463551

The kit is designed for PGP-00 and I-20-00. It allows you

to safely attach a shrub sprinkler to a piece of

5

⁄

16

"

rebar.

The kit comes with a heavy-duty locking tie to attach the

sprinkler to the kit.

NOZZ L E INSTA LL ATION

1. Insert the plastic key end of the Hunter wrench into

the lifting socket of the sprinkler and turn 90°. Pull the

riser up to gain access to the nozzle socket (Fig. 8).

2. Using the hex key of the

Hunter wrench, turn the radius

adjustment screw (Fig. 6)

counterclockwise to be sure

it is not blocking the nozzle

socket opening. If a nozzle

is already installed, it can

be removed by backing out the

adjustment screw and turning on the

water, or by pulling outward on the

nozzle removal post with a pair of

needle-nosed pliers.

3. Slip the desired nozzle into the

nozzle socket (Fig. 7). Note that the

socket is angled up 25°. Then tighten

the nozzle range screw. The triangle

on the rubber cover will always

indicate the location of the nozzle

and direction of water flow when the

sprinkler is retracted.

AL IG NIN G THE RI G HT (FIXED) SIDE OF ARC

If the right side of the arc is not properly aligned, the

results may be a wet walkway or a dry turf area. The right

side arc can easily be realigned. One way to realign the

right stop is to turn the whole sprinkler body assembly

and the fitting below it, left or right to the desired position.

This may require temporary removal of the soil around

the sprinkler to allow you to grip the sprinkler housing.

Another way to reset the right arc is to unscrew the body

cap counterclockwise and remove the internal assembly

from the body. Once removed, rotate the nozzle turret

to the right stop, screw the internal assembly back into

the body with the nozzle aligned to the right side of the

area you want irrigated (Fig. 9). At this point you have

realigned the right arc stop, and you can adjust the left

arc to an appropriate setting.

Note:

It is not necessary to dig up and remove the whole

sprinkler to realign the right arc.

TURNIN G F LOW ON OR OFF

Insert the plastic key end of the Hunter

wrench into the FloStop

®

adjustment

socket (Fig. 3 & 10). Turn wrench

clockwise to decrease or shut off the

flow. Turn the wrench

counterclockwise to

increase the flow.

Fig. 7

Nozzle Removal

Post

Fig. 10

Fig. 9

Model

Nozzle

No.

Pressure

in PSI

Degrees of

Trajectory

Max Height

of Spray (ft.)

Distance from head (ft.)

to Maximum Height

I-20

1.5

45

25

8'

23'

Blue

2.0

45

25

8'

23'

2.5

45

25

9'

26'

3.0

45

25

10'

28'

4.0

45

25

11'

30'

5.0

45

25

11'

30'

6.0

55

25

12'

32'

8.0

55

25

13'

32'

I-20

Low Angle

2.0

50

13

5'

22'

2.5

50

13

4'

22'

3.5

50

13

4'

22'

4.5

50

13

4'

22'

I-20

18' Short

Radius

.50

50

15

5'

8'

1.0

50

14

6'

9'

2.0

50

3

1'

6'

I-20

25' Short

Radius

.75

50

22

7'

13'

1.5

50

18

7'

13'

3.0

50

8

1'

6'

Plastic Ke y End

Steel He x End

NON -STRI PP ABL E B AC K DRI VE

This I-20 sprinkler is designed with an internal device that prevents damage to

the internal gear drive if it should be turned by vandals. This important feature

works when the nozzle turret is turning in either direction. This makes the

sprinkler very durable in all applications.

AUTO ARC RETURN

This I-20 sprinkler is designed with an

internal device that re-aligns the arc if it is

turned by vandals. This important feature

works when the nozzle turret is turning in

either direction. When forced outside of the

originally set arc, the sprinkler takes the

shortest path back to the pattern without

going completely around. This saves

the non-irrigated areas from getting wet!

Always a good thing!

a

uto

-retu

rn

if fo

rced

d

esire

d se

t a

rc

Fig. 3

A

R

C

ADS

O

F

F

I-20

Lifting

Socket

Nozzle

Locator/Radius

Adjustment

Screw

Model

Identification

Arc

Adjustment

FloStop

®

Fig. 8