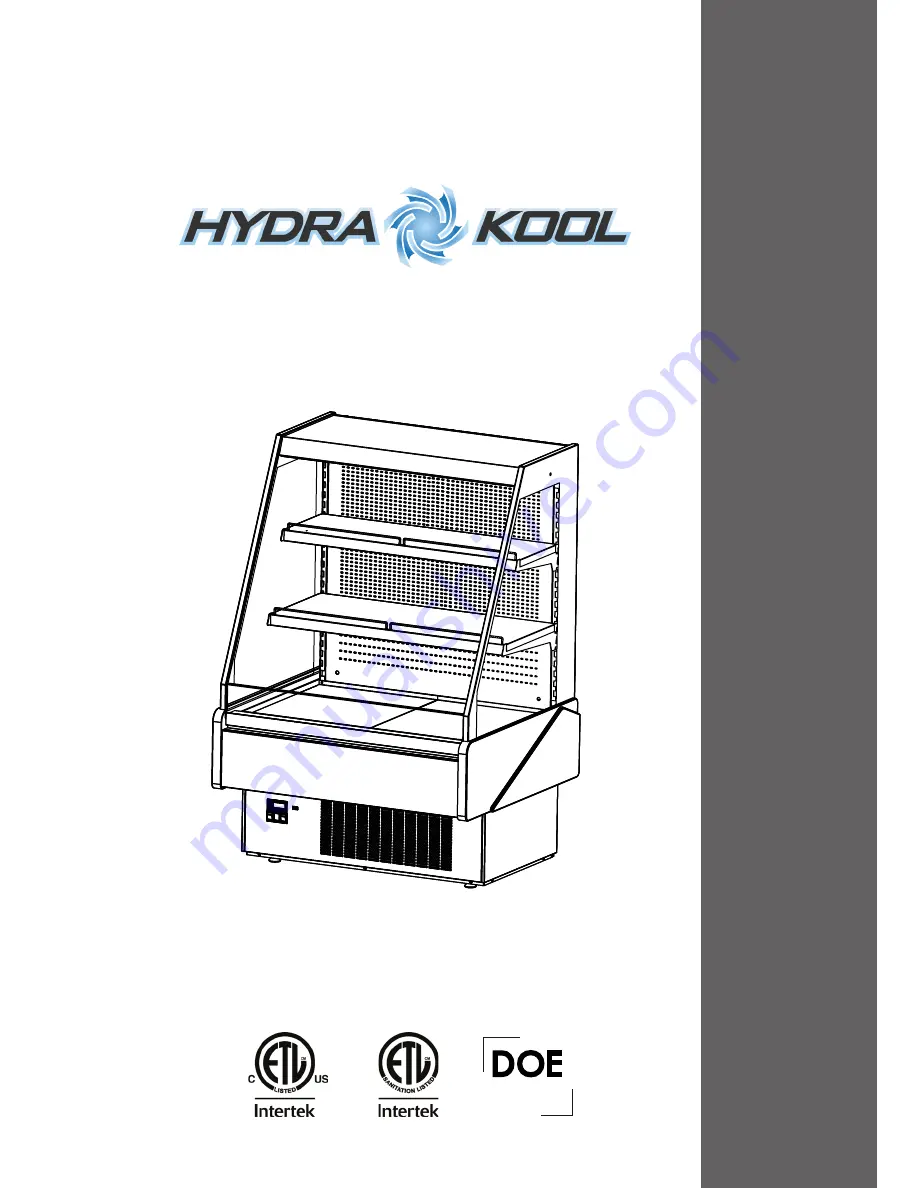

Summary of Contents for KGL SERIES

Page 1: ...DOE Compliant KGL SERIES INSTALLATION AND OPERATION MANUAL V0 ...

Page 4: ...4 This page has been left blank intentionally ...

Page 6: ...6 34 60 12 16 11 12 10 23 22 KGL SERIES KGL OF XX S R 41 KGL OF 40 S R ...

Page 7: ...7 50 61 KGL OF 50 S R KGL OF 60 S R ...

Page 8: ...8 KGL RS RM XX S R KGL RS RM 40 S R 41 36 60 12 16 11 12 10 23 23 ...

Page 9: ...9 KGL RS RM 50 S R KGL RS RM 60 S R 50 61 ...

Page 10: ...10 KGL DL XX S R 36 60 12 16 11 12 10 23 23 KGL DL 40 S R 41 ...

Page 11: ...1 1 KGL DL 50 S R 50 KGL DL 60 S R 61 ...

Page 12: ...12 KGL OS XX S R 34 12 16 65 22 23 12 10 11 KGL OS 40 S R 41 ...

Page 13: ...13 KGL OS 50 S R 50 KGL OS 60 S R 61 ...

Page 15: ...15 Front KGL OF 50 S R 34 6 26 25 5 8 9 5 3 2 12 47 2 ...

Page 16: ...16 KGL OF 60 S R 34 6 31 31 5 3 2 12 57 2 8 9 5 Front ...

Page 18: ...18 KGL RS RM 50 S R 34 6 26 25 5 8 9 5 3 2 12 47 2 4 2 Front ...

Page 19: ...19 KGL RS RM 60 S R 34 6 31 31 5 3 2 12 57 2 8 9 5 4 2 Front ...

Page 21: ...21 KGL DL 50 S R 34 6 25 26 5 8 9 5 3 2 12 47 2 Front ...

Page 22: ...22 KGL DL 60 S R 34 6 31 31 5 8 9 5 3 2 12 57 2 Front ...

Page 24: ...24 KGL OS 50 S R 34 6 25 26 5 8 9 5 3 2 12 2 3 7 37 Front ...

Page 25: ...25 KGL OS 60 S R 34 6 31 31 5 8 9 5 3 2 12 57 2 12 3 Front ...

Page 34: ...34 Self contained numbers Remote numbers ...

Page 44: ...44 2 9 Joining For joining follow the steps described KGL OF DL only ...

Page 46: ...46 KIT0004U01000 2x KGL DL ...

Page 47: ...47 2x 1x 1x 10 10 ...

Page 48: ...48 2X FIT00201301 189 G G ...

Page 55: ...55 Compressor Evap pan Fan Condenser Filter Controller ...

Page 102: ...102 Service by Type of action Date Serial number and model Service by ...

Page 104: ...104 8 Notes ...

Page 105: ...105 This page has been left blank intentionally ...

Page 106: ...106 This page has been left blank intentionally ...

Page 107: ...107 This page has been left blank intentionally ...