MSEP

First Step Guide

Fourth Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the product in addition to this First

Step Guide to ensure correct use.

This Instruction Manual is original.

•

Using or copying all or part of this Instruction Manual without permission is prohibited.

•

The company names, names of products and trademarks of each company shown in the sentences are registered

trademarks.

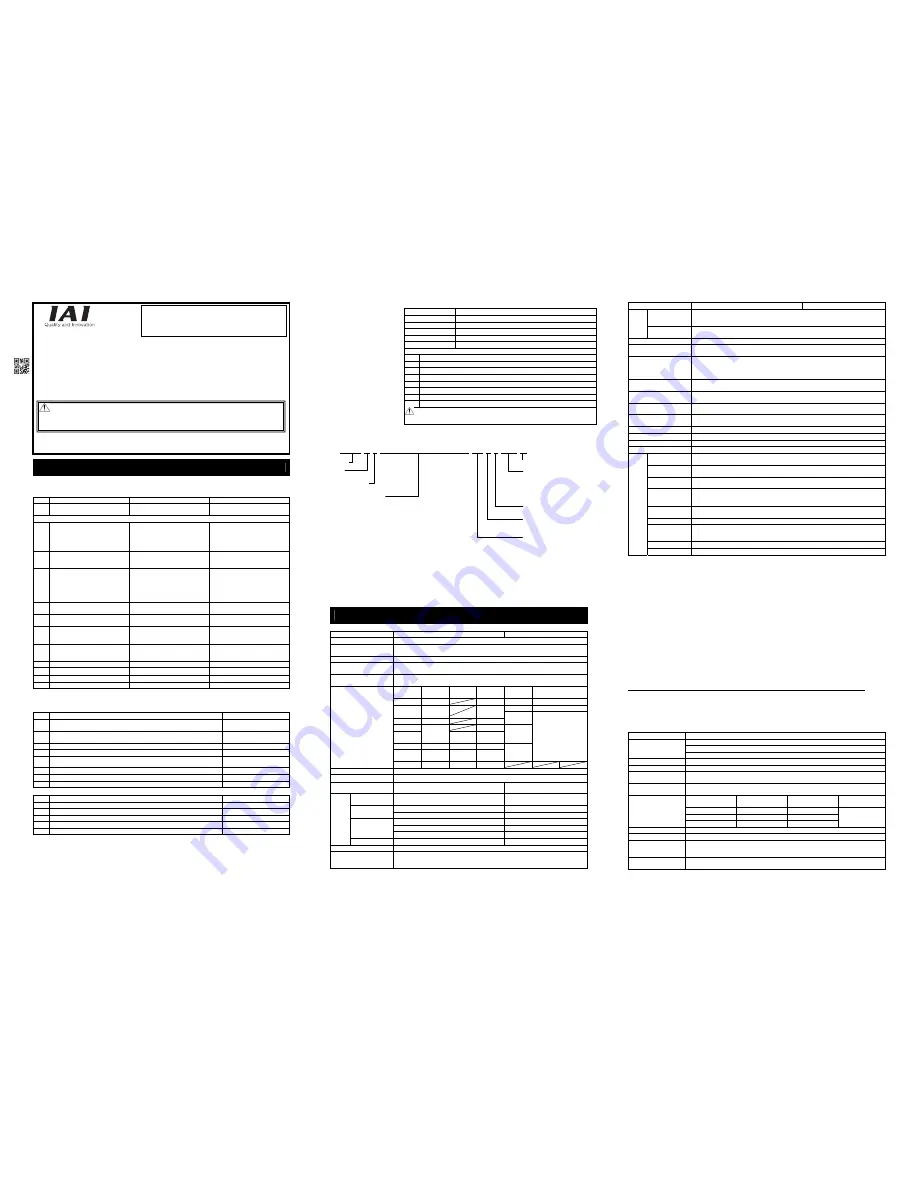

Product Check

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts

No. Part

Name

Model

Remarks

1 Controller

Main

Body

Refer to “How to read the model

plate”, “How to read the model No.”

Accessories

2 Power

Connector

FKC2.5HC/4-ST-5.08

(Supplier : PHOENIX CONTACT)

Recommended Cable Size

•

Control Power Supply

0.5 to 0.3mm

2

(AWG20 to 22)

•

Motor Driving Power Supply

2.5 to 0.5mm

2

(AWG12 to 20)

3

External Brake Input Connector

FMCD1.5/5-ST-3.5

(Supplier : PHOENIX CONTACT)

Recommended cable size

0.5 to 0.2mm

2

(AWG20 to 24)

4

Drive Cutoff/Emergency Stop Input

Connector

FMCD1.5/8-ST-3.5

(Supplier : PHOENIX CONTACT)

Recommended Cable Size

•

Emergency Stop

0.5 to 0.2mm

2

(AWG20 to 24)

•

Motor Power External Input

1.25 to 0.5mm

2

(AWG16 to 20)

5

System I/O Connector

FMCD1.5/4-ST-3.5

(Supplier : PHOENIX CONTACT)

Recommended cable size

0.5 to 0.2mm

2

(AWG20 to 24)

6

I/O Flat Cable (For PIO Type)

CB-MSEP-PIO***

***shows the cable length

(Example) *** : 020 = 2 [m]

7

CC-Link Connector

(For CC-Link Type)

MSTB2.5/5-ST-5.08 ABGY AU

(Supplier : PHOENIX CONTACT)

Terminal Resistance (130

Ω

1/2W,

110

Ω

1/2W)

enclosed one unit each

8

DeviceNet Connector

(For DeviceNet Type)

MSTB2.5/5-ST-5.08 ABGY AU

(Supplier : PHOENIX CONTACT)

Prepare a terminal resistor separately

if this controller is to be allocated at

the terminal.

9

Absolute Battery Box (Option)

MSEP-ABU (Battery AB-7)

For Simple Absolute Type

10

First Step Guide

11

Instruction Manual (DVD)

12 Safety

Guide

2. Teaching Tool (Please purchase separately)

A teaching tool such as PC software is necessary when performing the setup for position setting, parameter setting, etc.

that can only be done on the teaching tool.

Please prepare either of the following teaching tools.

No. Part

Name

Model

1

PC Software

(Includes RS232C Exchange A Peripheral Communication Cable)

RCM-101-MW

2

PC Software

(Includes USB Exchange A USB Cable + Peripheral Communication Cable)

RCM-101-USB

3

Teaching Pendant (Touch Panel Teaching)

CON-PTA

4

Teaching Pendant (Touch Panel Teaching with deadman switch)

CON-PDA

5

Teaching Pendant

(Touch Panel Teaching with deadman TP Adapter (RCB-LB-TG))

CON-PGA

6

Teaching Pendant (Touch Panel Teaching)

TB-01

7

Teaching Pendant (Touch Panel Teaching with deadman switch)

TB-01D

8

Teaching Pendant (Dead man’s switch right mounted touch panel teaching)

TB-01DR

3. Instruction manuals related to this product, which are contained in the instruction manual (DVD).

No. Name

Manual

No.

1

MSEP Controller Instruction Manual

ME0299

2

PC Software

RCM-101-MW/RCM-101-USB Instruction Manual

ME0155

3

Touch Panel Teaching CON-PTA/PDA/PGA Instruction Manual

ME0295

4

Touch Panel Teaching TB-01/TB-01D/TB-01DR Instruction Manual

ME0324

5

XSEL controller RC Gateway Function Instruction Manual

ME0188

4. How to read the model plate

Model

→

MODEL MSEP-C-5-20PI-N-42PI-PI-10I-20ILA-DV-2-0-ABU

Serial number

→

SEREIAL No.

SI-E18392

Manufactured date

→

PRODUCT DATE

2012/02/01

Manual No.

→

MANUAL No.

ME0299

CP INPUT

DC24V 2.0A

Input power supply

→

MP INPUT

DC24V 7.6A

AXIS No. /OUTPUT

0

0-24Vac 3ph 0-333Hz 1.0A

1

2

0-24Vac 3ph 0-333Hz 2.0A

3

0-24Vac 3ph 0-333Hz 2.0A

4

0-24Vac 3ph 0-333Hz 1.3A

5

0-24Vac 3ph 0-333Hz 1.3A

6

Information of the

connected axes

→

(Axis No. 0 to 7)

7

CAUTION: Connect the wiring correctly and properly.

use IAI Corporation specified cables.

Made In Japan

5. How to read controller model code

(Example) Consists of 5 axes: Axis No.0=pulse motor type, Axis No.2,3=servo motor type, Axis No.4=No connected axis and Axis

No.1=Ineffective axis

M S E P - C - 5 - 2 0 P W A I - P W A I - 1 0 I - 2 0 I - N - D V - 2 - 0 - A B U - * *

Basic Specifications

List of Specifications

Specification Item

Driver for Servo Motor

Driver for Pulse Motor

Number of Controlled Axes

8 axes MAX.

Control/Motor Power Supply

Voltage

24V DC

±

10%

Brake Power Supply

0.15A × Number of axes

Control Power Current

Consumption

0.8A

Control Power In-Rush

Current

MAX. 5A 30ms or less

Motor Type

Rated

Low power

MAX.

(Note 1)

Motor

Flange Size

MAX.

(Note 2)

2W

0.8A

4.6A

20P 2.0A

28P 2.0A

3W (RCD)

0.7A

1.5A

5W

1.0A

6.4A

35P

10W (RCL)

6.4A

10W

(RCA/RCA2)

1.3A

2.5A 4.4A

42P

20W

1.3A

2.5A

4.4A

20W

(20S Type)

1.7A 3.4A 5.1A

56P

2.0A

(High output invalid)

3.5A (Rated) /

4.2A (MAX.)

(High output valid)

(Note 4)

Motor Current Consumption

30W

1.3A

2.2A 4.4A

Motor Power In-Rush Current

Number of slots × MAX. 10A 5ms or less

Heat Generation

26W Max.

Control System

Vector control (Rectangular waveform drive only for

3W of the motor type)

Weak field-magnet vector control

RCA,

RCP2 to RCP5

All Types

800Pulse/rev

RCA2-

□□□

N 1048Pulse/rev

RCA2

Except for RCA2-

□□□

N 800Pulse/rev

RA1L • SA1L • SA4L • SM4L

715Pulse/rev

RA2L • SA2L • SA5L • SM5L

855Pulse/rev

RCL

RA3L • SA3L • SA6L • SM6L

1145Pulse/rev

Encod

e

r Resol

u

tion

RCD All

Types

400Pulse/rev

Actuator Cable Length

MAX. 20m (Note) 10m maximum for Simple Absolute type

Serial Communication

Interface

(SIO Port: Only for teaching)

RS485 1CH (based on Modbus Protocol) Speed 9.6 to 230.4kbps

Specification Item

Driver for Servo Motor

Driver for Pulse Motor

PIO Type

PIO Type:Signal I/O dedicated for 24V DC (to be selected when purchased NPN/PNP)

Number of max. input: 4 points per axis, Number of max. output: 4 points per axis

Cable length MAX. 10m

Exter

n

al

Inter

face

Field Network Type

DeviceNet, CC-Link, PROFIBUS-DP, CompoNet, EtherNet/IP, EtherCAT

(Reference) An operation by RC Gateway Function is available.

Data Setting and Input

PC Software, Touch Panel Teaching, Gateway Parameter Create Tool

Data Retention Memory

Position data and parameters are saved in the nonvolatile memory.

(There is no limitation in number of writing)

Number of Positioning Points

PIO Type: 2 or 3 points

Field Network Type: 256 points (There is no limit for simple direct and direct indication modes)

(The number of positioning points differs depending on the operation mode select by the

parameter setting.)

LED Display

(Mounted on Front Panel)

8 LED lamps for driver status display (for each driver board)

Status LED 4 points (PIO Type), 7 points (Field Network Type)

Electromagnetic Brake

Compulsory Release

Brake release available for each axis by compulsory release signal input (24V DC input)

Protective functions

(Note3)

Overcurrent Protection (Equipped with a built-in cutoff circuit using a semiconductor for each

slot)

Protection Function against

Electric Shock

Class I basic insulation

Insulation Resistance

500V DC 10M

Ω

Weight

620g, For simple absolute type, 690g plus 1950g for absolute battery box (for 8-axis type)

Cooling Method

Forced air-cooling

External Dimensions

123W × 115H × 95D

Surrounding Air

Temperature

0 to 40

°

C

Surrounding

Humidity

85%RH or less (non-condensing)

Surrounding

Environment

[Refer to Installation Environment]

Surrounding

Storage

Temperature

-20 to 70

°

C

0 to 40

°

C for absolute battery

Surrounding

storage humidity

85%RH or less (non-condensing)

Usable Altitude

1000m or lower above sea level

Vibration Durability

Frequency 10 to 57Hz/ Swing width : 0.075mm

Frequency 57 to 150Hz/ Acceleration : 9.8m/s

2

XYZ Each direction Sweep time: 10 min. Number of sweep: 10 times

Shock Resistance

150mm/s

2

11ms Semi-sine wave pulse XYZ Each direction 3 times

Envi

ronm

en

t

Protection Class

IP20

Note 1 The current becomes maximum when the excitation phase of the servo-motor is detected, which is performed during the

initial servo-motor ON processing after the power is injected. (Normal: Approx. 1 to 2 sec, MAX.: 10 sec).

Note 2 The current is maximized at the excitation phase detection conducted in the first servo-on process after the power is

supplied (ordinary 100ms).

Note 3 For servo-motor, the protection is triggered with the current greater in 1.4 times than the maximum load current.

Note 4 High-output type driver board can control one axis per board.

<

Calculation of 24V DC Power Capacity >

For the calculation of 24V DC power capacity, figure out the numbers for (1) to (5) below, and then follow Step (7).

(1) Control Power Current Consumption: 0.8A··························································································1)

(2) Current Consumption of Motor Power Supply:

Total of motor current consumption of connected actuator ······································································2)

(3) Current Consumption at Excitation Phase Detection:

Maximum current in the total of maximum motor current to turn the servo on at the same time ······················3)

(4) Control Power In-Rush Current: 5A····································································································4)

(5) Motor Power In-Rush Current: Number of slots × 10A ···········································································5)

(6) Current consumption of brake power supply: Number of actuators with brake × 0.15A·································6)

(7) Selection of Power Supply:

Usually, the rated current is to be approximately 1.3 times higher than 1) + 2) + 6) above considering approximately 30% of

margin to the load current. However, considering the current of 3) to 5), even though it is a short time, select a power

supply with “peak load corresponding” type or that with enough capacity. For the current of 3) to 5), it can be avoided from

the current consumption occurred at the same time by the timing for the emergency stop release (motor power-on) and

servo-on being changed. In the case that the capacity margin is not sufficient, voltage might be dropped in a moment. In

particular, be careful of the power unit with the remote sensing function.

(Note) Make short-circuit on 0V side when separate power sources are used for the control power and motor power.

(Reference)

Selection of Power Supply Protection Circuit Breaker

It is recommended that the power supply protection is conducted on the primary side (AC power side) of the 24V DC power

supply unit.

Pay attention to the in-rush current of 24V DC power supply unit and rated cutoff current of the circuit breaker.

• Rated Breaking Current > Short-circuit Current = Primary Power Supply Capacity/Power Voltage

• (Reference) In-rush Current of IAI Power Supply Unit PS241 = 50 to 60A, 3msec

●

Specifications of DeviceNet Interface

Item Specification

DeviceNet2.0

Group 2 Dedicated Server

Communication Protocol

Network-Powered Insulation Node

Baud Rate

Automatically follows the master

Communication System

Master-Slave System (Polling)

Number of Occupied

Channels

MAX. 16CH (Input, Output)

Number of Occupied

Node

1 node

Baud Rate

Max. Network Length

Total Branch Line

Length

Max. Branch Line

Length

500kbps 100m 39m

250kbps 250m 78m

Communication Cable

Length

(Note 2)

125kbps 500m 156m

6m

Communications Cable

Use the dedicated cable.

Connector

(Note 1)

MSTBA2.5/5-G-5.08-ABGY AU (Manufactured by PHOENIX CONTACT or equivalent)

Consumption Current of

Communication Power

Supply

60mA

Communication Power

Supply

24V DC (Supplied from DeviceNet)

Note 1 The cable-side connector is a standard accessory. (PHOENIX CONTACT MSTB2.5/5-ST-5.08ABGY AU)

Note 2 For T branch communication, refer to the Instruction Manuals for the master unit and programmable controller (PLC)

to be mounted.

<Series>

<Type>

C :Standard Type

<Connected Axes>

1 to 8: Number of driver axes

<Detail of Connected Axis>

[Pulse Motor Type]

[Servo Motor Type]

20P :

20

□

pulse motor

2

: 2W servo motor

20SP : 20

□

pulse motor

5

: 5W servo motor

28P :

28

□

pulse motor

5S : 5W servo motor

28SP : 28

□

pulse motor

10 : 10W servo motor

35P :

35

□

pulse motor

20 : 20W servo motor

42P :

42

□

pulse motor

20S : 20W servo motor

56P :

56

□

pulse motor

30 : 30W servo motor

3D : 3W brushless DC electric motor

P : Ineffective axis (Pulse motor)

A

: Ineffective axis (Servo motor)

N : Not connected

[Encoder Type]

WAI : Incremental / Battery-less Absolute Shared (Pulse Motor Type)

I

: Incremental (Servo Motor Type)

SA

: Simple Absolute (Pulse Motor / Servo Motor)

[Option] (if servo motor is selected)

HA

: High Acceleration/Deceleration Type (when servo motor selected)

LA

: Low Power Consumption Type (when servo motor selected)

T

: High-Output Setting Type (when actuator selected)

<Identification for IAI use only>

* There is no identification in some cases

<Applicable for Simple Absolute Type>

ABB :

Simple

Absolute

Type

(with absolute battery)

ABBN :

Simple

Absolute

Type

(with no absolute battery)

No indication : Incremental

<Power Voltage>

0 : 24V DC

<I/O Cable Length>

0 : No cable

2 : 2m (Standard)

3 : 3m

5 : 5m

<I/O Type>

NP : NPN Type (Sink type) (Standard)

PN : PNP Type (Source type)

DV : DeviceNet Type

CC : CC-Link Type

PR : PROFIBUS-DP Type

CN : CompoNet Type

EP : EtherNet/IP Type

EC : EtherCAT Type

Warning : Operation of this equipment requires detailed installation and operation instructions which are

provided on the DVD Manual included in the box this device was packaged in. It should be retained

with this device at all times.

A hardcopy of the Manual can be requested by contacting your nearest IAI Sales Office listed at

the back cover of the Instruction Manual or on the First Step Guide.

Field Network Type

(DeviceNet, CC-Link, PROFIBUS, CompoNet,

EtherNet/IP, EtherCAT)