Summary of Contents for Power System 8335-GTW

Page 1: ...Power Systems Servicing the 8335 GTW IBM...

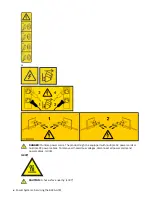

Page 14: ...xiv Power Systems Servicing the 8335 GTW...

Page 204: ...190 Power Systems Servicing the 8335 GTW...

Page 234: ...220 Power Systems Servicing the 8335 GTW...

Page 245: ......

Page 246: ...IBM...