GP SERIES BENCHES

TOOLS REQUIRED FOR ASSEMBLY

Socket set, Open end wrench set, Cordless

drill with 3/8" socket bit (Magnetic recommended).

BEFORE ASSEMBLY

Read through the assembly instructions to

familiarize yourself with the order in which

the parts are assembled. We suggest that

you clear & vacuum the area where the bench

is to be assembled. It is important that the

bench is assembled in the same sequence

as instructed.

HARDWARE

All assembly hardware is provided.

Thread 1 thin nut onto the leveler.

Place leveler into floor-mount hole at

the base of the leg or the base of the insert

if its an adjustable height bench. Thread the top

nut onto the leveler.

Loosen & tighten nuts to adjust the height

of your work bench.

STEP 1

**SKIP THIS STEP IF YOU HAVE NOT PURCHASED THE LEVELER OPTION**

LEVELER KIT OPTION

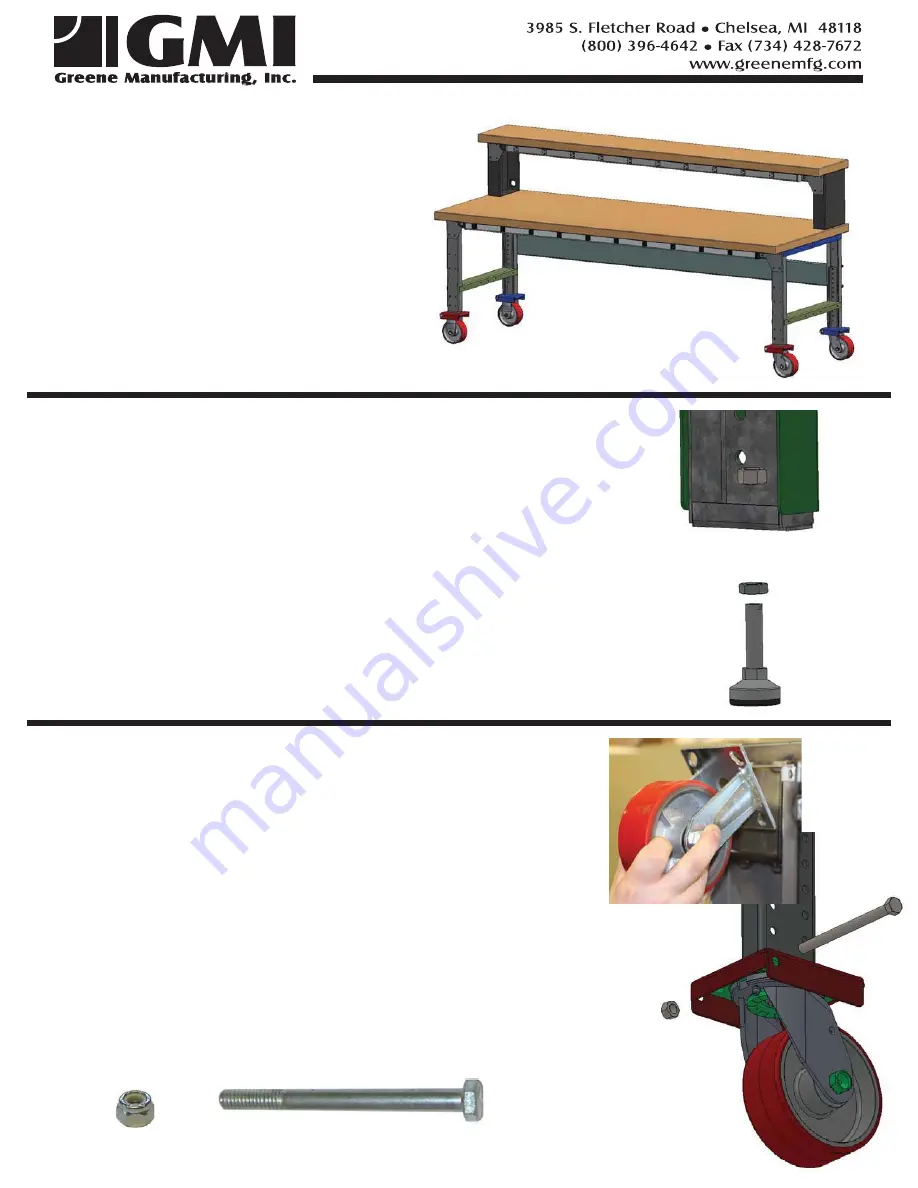

STEP 2

**SKIP THIS STEP IF YOU HAVE NOT PURCHASED THE CASTER OPTION**

MOBILE CASTER KIT OPTION

Nylock Nut

Attach the single bolt casters to the bottom of the legs

or the base of the insert if

its an adjustable height bench.

.

NOTE: TWO TYPES OF CASTERS ARE PROVIDED (SWIVEL AND FIXED) BE SURE TO USE

TWO OF THE SAME TYPE AT EACH END OF THE BENCH (TWO SWIVEL CASTERS ON

THE RIGHT AND TWO FIXED ON THE LEFT). ALSO BE SURE THE FIXED CASTERS ARE

POSITIONED SO THE GREASE ZERK IS ACCESSIBLE FROM THE OUTSIDE OF THE

BENCH (SEE FIG. 2). IF ALL SWIVEL CASTERS ARE ORDERED, PLACEMENT WILL NOT

BE IMPORTANT.

Insert the top of the caster into the angled lip pocket (this will be the side opposite

of the bolt holes), tilt the caster flat against the mounting plate until the bolt is

able to be slid behind the caster, locking it in place. Bolt in place using (1) 3/8” x

4-3/4” long hex head bolt and 3/8” nylock nut. Repeat steps for the other caster

locations.

3/8” x 4-3/4”

Flange Head Bolt