INGERSOLL RAND COMPANY LTD

209 NORTH MAIN STREET – BRYAN, OHIO 43506

(800) 495-0276

FAX (800) 892-6276

© 2019

arozone.com

OPERATOR’S MANUAL

PP10A-XXX-XXX-A

INCLUDING: OPERATION, INSTALLATION AND MAINTENANCE

RELEASED: 5-25-18

REVISED: 2-15-19

(REV: C)

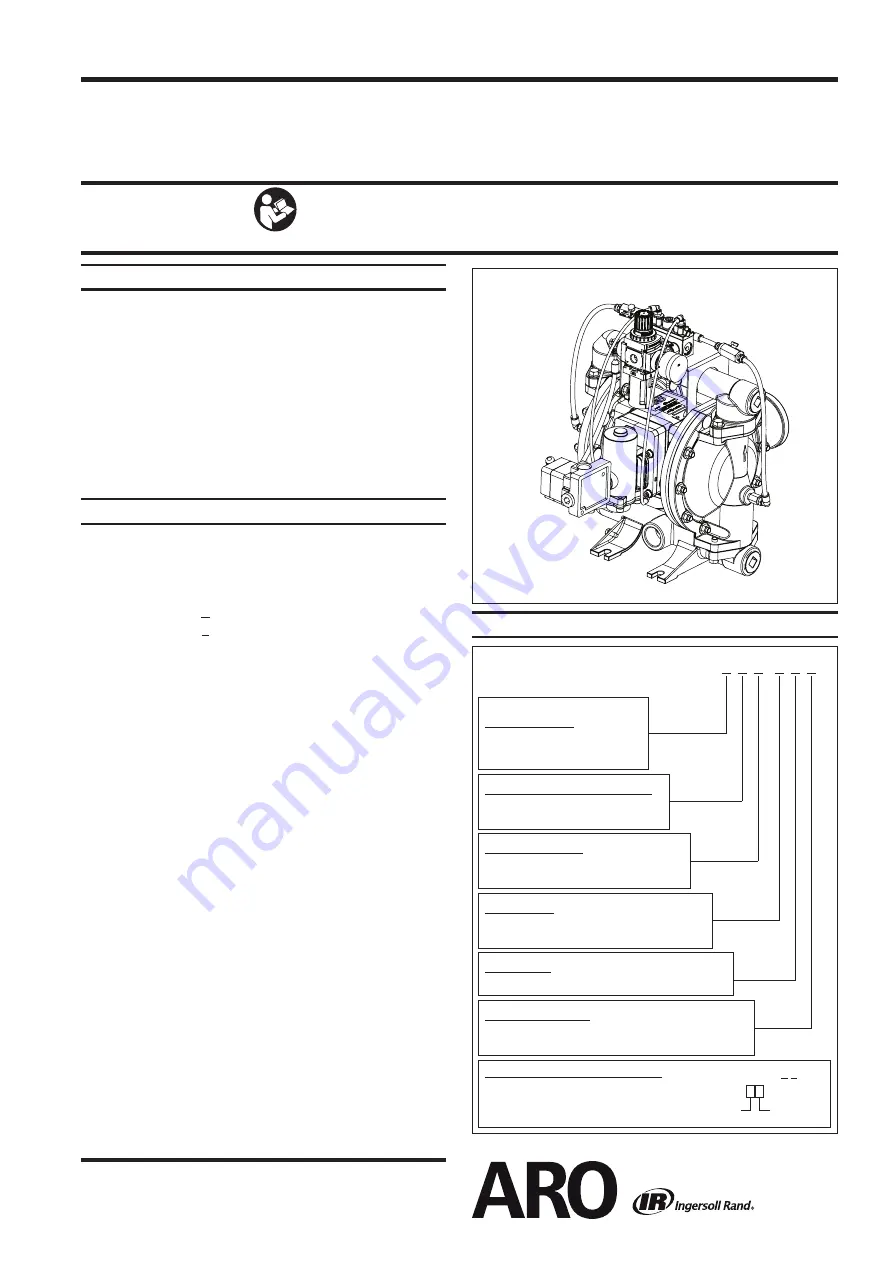

1” DRY POWDER DIAPHRAGM PUMP

1:1 RATIO (METALLIC)

READ THIS MANUAL CAREFULLY BEFORE INSTALLING,

OPERATING OR SERVICING THIS EQUIPMENT.

It is the responsibility of the employer to place this information in the hands of the operator. Keep for future reference.

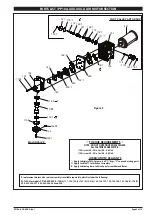

SERVICE KITS

Refer to Model Description Chart to match the pump mate-

rial options.

7102

Valve Kit for repair of H254PS control valve.

104302

for repair of P39124-100 Filter / Regulator.

637401-XXX

for Fluid Section repair

with

seats (see page 6).

637401-XX

for Fluid Section repair

without

seats (see page 6).

NOTE:

This kit also contains several air motor seals which will

need to be replaced.

118597-2

Spool Kit for repair of A212PD 4-way alpha valve.

637397

for Air Section repair (see page 8).

637395-8

Major Air Valve assembly (see page 9).

PUMP DATA

Models

. . . . . . . . . . . . . see Model Description Chart for “-XXX”

Pump Type

. . . . . . . . . Metallic, Dry Powder, Diaphragm Pump

Material

. . . . . . . . . . . . see Model Description Chart

Specific Application

for pumping powders up to 50 lb. / ft

3

Weight

. . . PP10X-XAX-XXX-AXXX . . . . 28.65 lbs (12.97 kgs)

PP10X-XSX-XXX-AXXX . . . . 46.2 lbs (20.9 kgs)

Maximum Air Inlet Pressure

. . . . . . . . 50 psig (3.4 bar)

Maximum Fluidizing Pressure

. . . . . . 100 psig (6.9 bar)

Maximum Particle Size

. . . . . . . . . . . . . 1/8” dia. (3.3 mm)

Maximum Temperature Limits (diaphragm / ball / seat

materials)

Santoprene

®

. . . . . . . . . . . . . -40° to 225° F (-40° to 107° C)

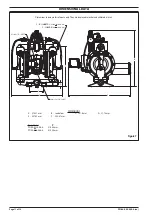

Dimensional Data

. . . . . . . . . . . . . . . . . . . see page 11

Mounting Dimension

. 4” x 6.25” (101.6 mm x 158.8 mm)

Noise Level

@ 70 psig, 60 cpm

. . . . . . 80.6 dB(A)

Tested with 94085 muffler assembly installed.

The pump sound pressure levels published here have been updated to

an Equivalent Continuous Sound Level (LA

eq

) to meet the intent of ANSI

S1.13-1971, CAGI-PNEUROP S5.1 using four microphone locations.

NOTICE: All possible options are shown in the chart, however, certain

combinations may not be recommended. Consult a representative or

the factory if you have questions concerning availability.

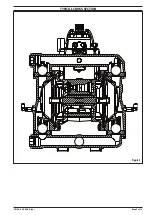

Figure 1

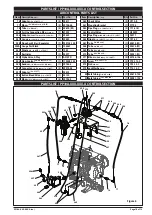

MODEL DESCRIPTION CHART

PP10A - X X X - X X X

Fluid Connection

A - 1 - 11-1/2 NPTF - 1

B - 1 - 11 BSP

Ball Material

A - Santoprene

Fluid Section Service Kit Selection

EXAMPLE: Model #PP10A-AAS-AAA

Fluid Section Service Kit # 637401-AA

PP10A - XXX - X X X

Ball

Diaphragm

637401 - X X

Fluid Cap and Manifold Material

A - Aluminum

S - Stainless Steel

Diaphragm Material

A - Santoprene

M - Medical Grade Santoprene

Seat Material

A - Santoprene

S - Stainless Steel

Hardware Material

P - Plated Steel

S - Stainless Steel

PP10A-XXX-XXX-A Powder Pump