S

SA

AF

FE

ET

TY

Y W

WA

AR

RN

NIIN

NG

G

Only qualified personnel should install and service the equipment. The installation, starting up, and servicing of heating, ventilating, and

air-conditioning equipment can be hazardous and requires specific knowledge and training. Improperly installed, adjusted or altered

equipment by an unqualified person could result in death or serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

February 2017

1

18

8--C

CE

E0

01

1D

D1

1--1

1F

F--E

EN

N

D345855P01

Upflow/Horizontal and Downflow

Gas-Fired, Direct/Non-Direct Vent, 2–Stage

Condensing Variable Speed Furnaces

U

Up

pffllo

ow

w,, C

Co

on

nv

ve

errttiib

blle

e tto

o

H

Ho

orriizzo

on

ntta

all R

Riig

gh

htt o

orr

H

Ho

orriizzo

on

ntta

all L

Le

efftt

S9V2B040U3PSBA

S9V2B060U3PSBA

S9V2B060U4PSBA

S9V2B080U3PSBA

S9V2B080U4PSBA

S9V2C080U5PSBA

S9V2C100U4PSBA

S9V2C100U5PSBA

S9V2D120U5PSBA

D

Do

ow

wn

nffllo

ow

w O

On

nlly

y

S9V2B040D3PSBA

S9V2B060D3PSBA

S9V2B080D3PSBA

S9V2B080D4PSBA

S9V2C100D4PSBA

S9V2C100D5PSBA

S9V2D120D5PSBA

N

No

otte

e:: Graphics in this document are for representation

only. Actual model may differ in appearance.

Installer’s Guide

Summary of Contents for S9V2B040D3PSBA

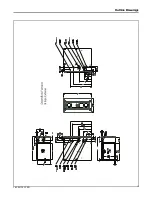

Page 12: ...12 18 CE01D1 1F EN Outline Drawings...

Page 13: ...18 CE01D1 1F EN 13 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 14: ...14 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 15: ...18 CE01D1 1F EN 15 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 16: ...16 18 CE01D1 1F EN O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...

Page 17: ...18 CE01D1 1F EN 17 O Ou ut tl li in ne e D Dr ra aw wi in ng gs s...