CARBON MONOXIDE POISONING AND FIRE

HAZARD

Failure to follow this warning could result in

personal injury, death, and/or property dam-

age.

This furnace is not designed for use in mobile

homes, trailers or recreational vehicles.

!

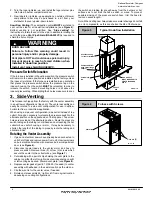

ELECTRIC SHOCK HAZARD

Failure to follow this warning

could result in injury and/or

death.

Turn OFF all power, lockout and

tag with suitable warning label

before servicing.

!

International Comfort Products, LLC

Lewisburg, TN 37091 U.S.A.

See section 5 for Category

I

definition.

INSTALLER: Affix these instructions

on or adjacent to the furnace.

CONSUMER: Retain these

instructions for future reference.

Portions of the text and tables are reprinted from ANSI Z223.1/NFPA 54

!

2009

, with permission of National Fire Protection Association, Quincy, MA 02269 and American Gas Association, Wash-

ington, DC 20001. This reprinted material is not the complete and official position of the NFPA or ANSI, on the referenced subject, which is represented only by the standard in its entirety.

WARNING

WARNING

WARNING

* Denotes Brands (C, H, T)

Printed in U.S.A.

441 01 2613 05

Sept. 2009

80+ SINGLE STAGE GAS FURNACE

Category I Furnace

N8MPN/N8MPL & *8MPN/*8MPL

Upflow/Downflow/Horizontal

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance, or use can cause explosion, fire, electrical shock, or other conditions

which may cause death, personal injury, or property damage. Consult a qualified installer, service agency, or your distributor or branch for

information or assistance. The qualified installer or agency must use factory

!

authorized kits or accessories when modifying this product.

Refer to the individual instructions packaged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses, protective clothing, and work gloves. Use quenching cloth for brazing operations. Have fire

extinguisher available. Read these instructions thoroughly and follow all warnings or cautions included in literature and attached to the unit.

Consult local building codes, the current editions of the National Fuel Gas Code (NFCG) NFPA 54/ANSI Z223.1, National Electrical Code

(NEC) NFPA 70.

In Canada refer to the current editions of the National standards of Canada CAN/CSA

!

B149.1 and .2 Natural Gas and Propane Installation

Codes, and Canadian Electrical Code CSA C22.1.

Recognize safety information. This is the safety

!

alert symbol

. When you see this symbol on the unit and in instructions or manuals, be

alert to the potential for personal injury. Understand these signal words; DANGER, WARNING, and CAUTION. These words are used with

the safety

!

alert symbol. DANGER identifies the most serious hazards which

will

result in severe personal injury or death. WARNING

signifies hazards which

could

result in personal injury or death. CAUTION is used to identify unsafe practices which

may

result in minor

personal injury or product and property damage. NOTE is used to highlight suggestions which

will

result in enhanced installation, reliability,

or operation.

Table of Contents

1. Safe Installation Requirements

3

. . . . . . . . . . . . . . . .

2. Installation

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Side Venting

8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Combustion & Ventilation Air

9

. . . . . . . . . . . . . . . . . .

5. Gas Vent Installation

12

. . . . . . . . . . . . . . . . . . . . . . . .

6. Horizontal Venting

13

. . . . . . . . . . . . . . . . . . . . . . . . .

7. Masonry Chimney Venting

15

. . . . . . . . . . . . . . . . . . .

8. Gas Supply and Piping

18

. . . . . . . . . . . . . . . . . . . . . .

9. Electrical Wiring

21

. . . . . . . . . . . . . . . . . . . . . . . . . . .

10.Ductwork and Filter (Upflow/Horizontal)

22

. . . . . . . .

11. Ductwork and Filter (Downflow)

25

. . . . . . . . . . . . . . . .

12. Checks and Adjustments

27

. . . . . . . . . . . . . . . . . . . . . .

13. Furnace Maintenance

32

. . . . . . . . . . . . . . . . . . . . . . . .

14. Sequence of Operation & Diagnostics

33

. . . . . . . . . . . .

15.Technical Support Manual

35

. . . . . . . . . . . . . . . . . . . . .

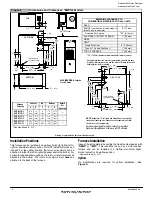

16.Model Specificications

36

. . . . . . . . . . . . . . . . . . . . . . . .

17.Circulation Data & Bellyband Placement

31

. . . . . . . . . .

18.Wiring Diagram

42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19.Parts Information Guide

43

. . . . . . . . . . . . . . . . . . . . . .

National Excelsior Company

www.excelsiorhvac.com

Subject to change without notice.