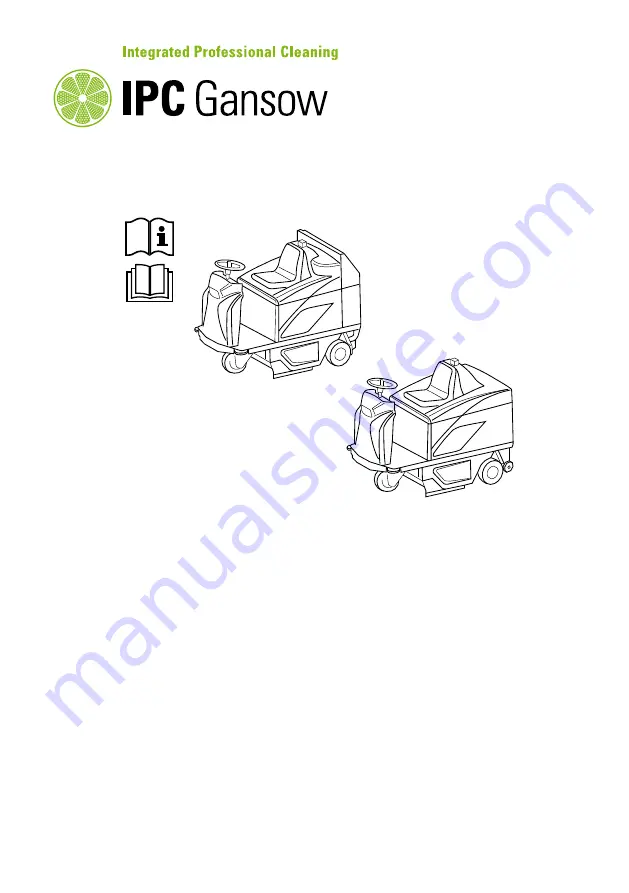

1250 - 1280

MANUALE ISTRUZIONI PER L’USO /

OPERATOR’S MANUAL / MANUEL D’INSTRUCTIONS /

BEDIENUNGSANLEITUNG /

MANUAL DE INSTRUCCIONES / BRUKERHÅNDBOK /

GEBRUIKERSHANDLEIDING / MANUAL DE UTILIZAÇÃO /

INSTRUKTIONSBOK / МАШИНА ДЛЯ МОЙКИ И СУШКИ ПОЛОВ

/ KULLANIM KILAVUZU

Consultare attentamente questo manuale prima di procedere a qualsiasi intervento sulla macchina

Read this manual carefully before carrying out any work on the machine

Lire attentivement ce manuel avant toute intervention sur la machine

Vorliegendes Handbuch vor jedem Eingriff an der Maschine aufmerksam durchlesen

Consulte detenidamente este manual antes de llevar a cabo cualquier trabajo en la máquina

Konsulter denne håndboken nøye før du går i gang med noen som helst type inngrep på maskinen

Raadpleeg deze handleiding aandachtig alvorens met enige werkzaamheid aan de machine te beginnen

Consulte atentamente este manual antes de efectuar qualquer intervenção na máquina

Läs noggrant igenom denna handbok innan du utför något som helst ingrepp på maskinen

Внимательно ознакомьтесь с данной инструкцией до проведения любой работы с машиной

Makine ile herhangi bir işlem yapmadan önce bu kılavuzu dikkatle okuyun